A grain thrower is an agricultural machine meant for quick loading of grain into the transport vehicles, formation, throwing over, and turning of the piles of grain in the elevators, grain warehouses, and grain bins. It is possible to clean grain of light impurities with the help of grain throwers.

The use of grain throwers of our manufacture is much more profitable and effective than the use of auger-type grain loaders and other conventional grain transfer technologies. The drawbacks of an auger-type grain loader lie in the grain coarse crushing when an auger is operated, it shall be transferred by hand, the distance of grain transfer is limited by the length of an auger while its capacity is not large. The use of the grain throwers of our manufacture ensures the minimum grain crushing, they can move by themselves, the grain flying range reaches 25 meters with the performance of 170 tons per hour.

Our grain throwers as distinguished from the vacuum grain loaders consume several-fold less electric power and have high performance.

Grain throwers

and grain loaders

We are manufacturing the best innovative models of grain throwers, which are characteristic of high performance, reliability, safety, maneuverability, and usability.

The advantages of a grain thrower in comparison with auger loaders:

- the grain thrower moves independently and loads itself with grain without the help of other machines or people, and the auger must be constantly moved manually;

- the distance of grain movement is limited by the length of the auger, the grain is poured down at the end of the auger. At the grain thrower, the grain does not fall out down, but flies out to a distance of 25 meters;

- when loading with a grain thrower, the transport can remain in place, and when loading with a screw, the transport must move after the auger;

- the width of the grain picking up by the grain thrower is 6 meters, and the auger is 10 times less;

- during the operation of the grain thrower, no more than 0.15% of the grain is damaged, and the auger has many times more;

- changing the direction, distance or height of grain loading at the grain thrower is much faster - in just 3 seconds;

- in the process of loading or transferring grain with a grain thrower, moisture and grain contamination is reduced. During the operation of the auger loader, the moisture content and grain contamination do not decrease.

The advantages of a grain thrower in comparison with pneumatic (vacuum) grain loaders:

- the grain thrower moves independently and loads itself with grain without the help of other machines or people, and the pneumatic loader and its part sucking up the grain must be constantly moved manually;

- a grain thrower can move grain higher than a pneumatic loader;

- during the operation of the grain thrower, no more than 0.15% of the grain is damaged, and for a pneumatic loader many times more;

- when loading with a grain thrower, the transport can remain in place, and when loading with a pneumatic loader, the transport must move after it;

- the grain thrower in the process of operation consumes no more than 0.1 kW / hour of electricity for loading 1 ton of grain. A pneumatic loader consumes many times more electricity and creates a large load on the power grid;

- the grain thrower, depending on the model, has a capacity of up to 170 tons per hour, which allows it to load transport or move grain faster than a pneumatic loader;

- the width of the grain picking up by the grain thrower is 6 meters, and the pneumatic loader is 10 times less;

- a grain thrower can load grain under the very roof of the warehouse, but a pneumatic loader cannot do this because it needs a place under the roof to locate a funnel through which the grain is poured;

- changing the direction, distance or height of grain loading at the grain thrower is much faster - in just 3 seconds;

- a grain thrower, its maintenance and maintenance is many times cheaper than a pneumatic loader.

Advantages of a grain thrower in comparison with a front loader:

- to move grain, the front loader must constantly move along with the grain, and therefore there is a risk of accidents and collisions with people. In the process of work, the grain thrower picks up grain from the surface of the warehouse and does not go anywhere with it, but throws it to another place or loads it into a transport;

- during the operation of the front loader, expensive fuels and lubricants are consumed and there is a risk of fire, a lot of smoke and harmful emissions that people breathe. The grain thrower in the process of operation consumes no more than 0.1 kW / hour of electricity for loading 1 ton of grain, there is no risk of fire, smoke and harmful emissions;

- during operation, the front loader drives over the grain and presses it down when lowering the bucket, and therefore a significant amount of grain is damaged. During the operation of the grain thrower, no more than 0.15% of the grain is damaged;

- the grain thrower, depending on the model, has a capacity of up to 170 tons per hour, which allows it to load transport faster than a front loader;

- the front-end loader pours grain from the bucket next to itself, the loading height is much lower than that of the grain thrower;

- a grain thrower can load grain under the very roof, but a front loader cannot do this because it needs a place under the roof to raise and empty a bucket with grain;

- a grain thrower, its maintenance and maintenance is many times cheaper than a front loader;

- a grain thrower is a very simple agricultural machine, for the control of which there is no need to obtain special permits, and to operate a front loader you need to undergo training and obtain a special permit;

- in the process of loading or transferring grain with a grain thrower, moisture and grain contamination is reduced. During the operation of the front loader, the moisture content and grain contamination do not decrease;

- the width of the grain picking up by the grain thrower is 6 meters, and the front loader is much smaller.

Patented innovative solutions are embodied in the design of our grain throwers:

- the design of trimming machine, which we have developed, prevents dust buildup, ensures minimum grain damage, large resource and automatic belt aligning

- the pipe of trimming machine can be easily adjusted for height from 2.5 to 4.5 m, rotate and has an original design making it possible to increase the distance and clustering of grain flight

- the availability of 4 automobile wheels, differential gear, and remote-control panel having considerably increased the maneuverability and facilitated the grain thrower control

- the voltage of controlling and lighting system of our grain throwers is 24 volts, the entire design is maximally convenient and safe

- high performance (up to 170 tons per hour) and minimum power consumption equalling to 0.07 kWh per ton of grain

All grain throwers manufactured by our Plant have the superior performance capabilities and perfect quality winning the awards for that on a regular basis. The State Management of Affairs awarded the grain throwers manufactured by our Plant as the best goods in the nomination “Development and Manufacturing of the Agricultural Machinery and Equipment”. The Agricultural Machinery Plant was rendered the best manufacturer of the agricultural machinery for six years in succession at the exhibitions AGRO-2013-2018, and the Ministry of Agrarian Policy and Food of Ukraine awarded us with the gold medals.

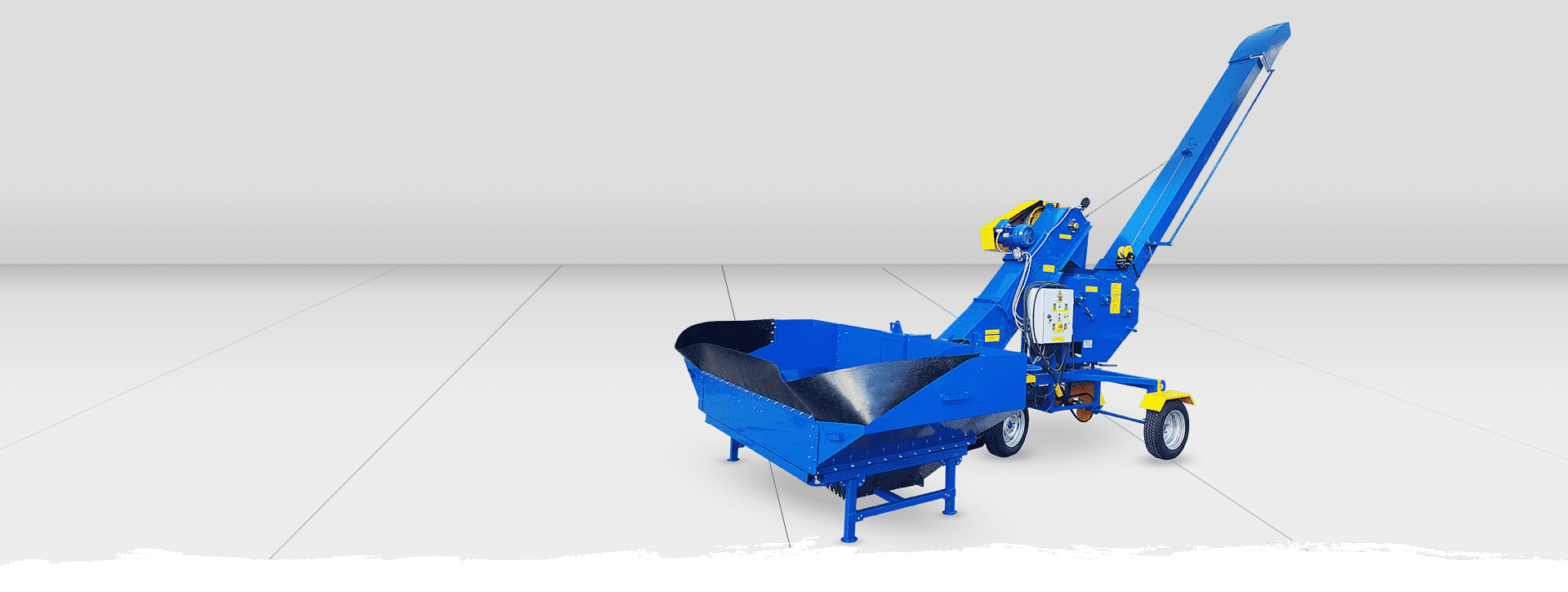

The Agricultural Machinery Plant offers for sale the grain loaders and grain throwers of different modifications. The grain thrower PZM-120M is the basic model having the performance up to 120 tons per hour and will be excellently suitable for small and medium-sized farm enterprises. High-powered grain thrower PZM-170 with a performance up to 170 tons per hour will be ideally suitable for the large-scale farm enterprises, Corn Traders, and agricultural holdings.

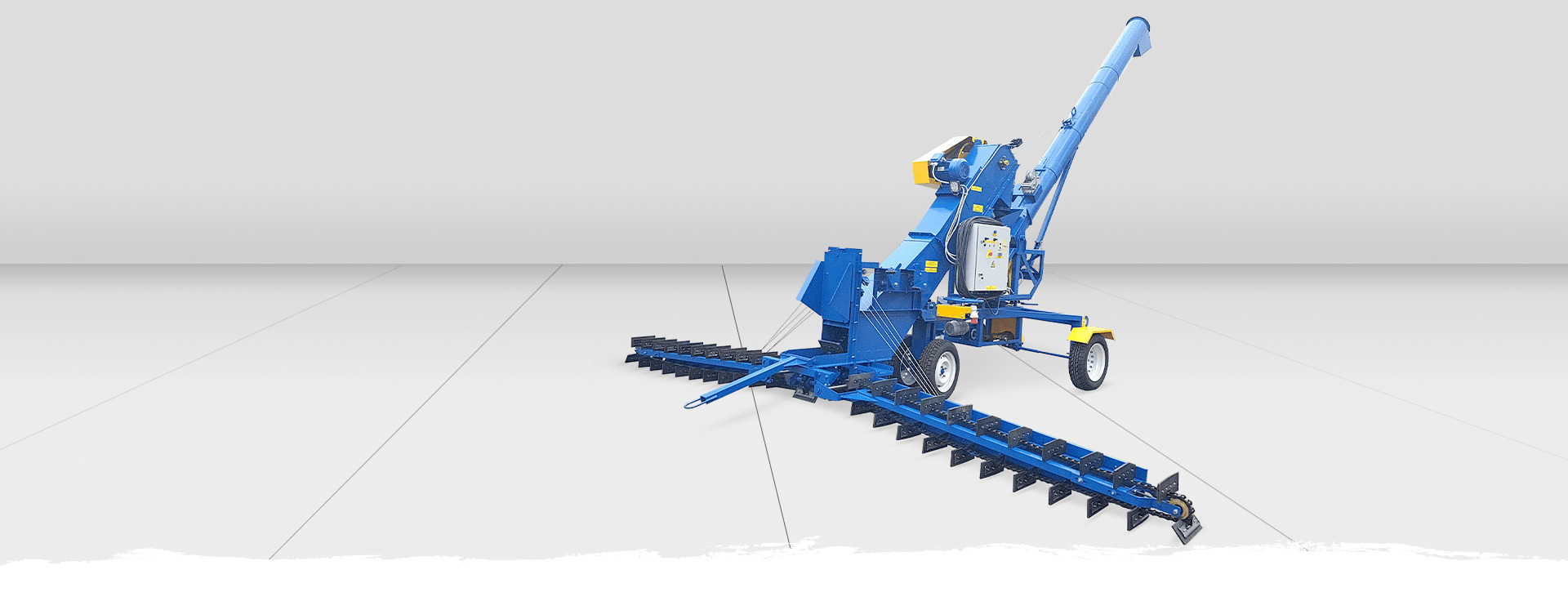

You can choose a model of grain thrower outfitted with the loading hopper PZM-120B or PZM-170B. In this case, the grain gets on the transporting conveyor from the loading hopper, which is very convenient for work with the grain carriers or the loading systems of warehouses. Another variant is to buy ZUBR multipurpose hopper-type grain thrower PZM-170 being simultaneously outfitted with the scrapper feeders and hopper.

The grain thrower PZM-120K or PZM-170K having a special design of the pipe of trimming machine, which makes it possible effectively load a container of any size, will be an ideal fit for the loading of containers.

The reliability, efficiency, safety, workability, and facility in operation are the main characteristics of our grain throwers. We are manufacturing quality agricultural machinery being in demand in Ukraine, European Union, and other countries. It is exceedingly profitable for the buyers to purchase the grain throwers from the Agricultural Machinery Plant. A price for the grain throwers of our own manufacture is very attractive.

You can purchase the most up-to-date grain throwers at our Plant, which will help you to work with the grain quickly and efficiently. The machinery may be delivered to any country of the world.

Apply the best innovative agricultural machinery manufactured by the Agricultural Machinery Plant, work easily and with comfort!