The PZM-170P mobile handler with a conveyor is designed to receive any grain, seeds, granules, pellets in a granary, grain cleaning complex, as well as quick transshipment of bulk cargo from trucks, trailers and other vehicles to any loaders, ships in the port, on the railway or in any other place. This portable handler can also be used to transfer grain from grain trucks to other transport equipment, elevators, augers, belt conveyors, big bags, etc.

The Agricultural Machinery Plant produces a whole range of mobile grain loaders designed for use in farms, grain receiving points, elevators, ports on the railway and just in the field. They differ in volume, overall dimensions and adaptation to different models of conveyors. Portable grain loaders of our production have a simple reliable design using components from the best European manufacturers.

The productivity of a mobile grain handler depends on the type of grain or other bulk cargo and reaches 200 tons per hour. Electricity consumption for reloading 1 ton of grain is only 0.04 kW. The portable grain handler PZM-170P can be additionally equipped with a chute rotating in different directions and rising up and down. Thanks to this chute, the range of grain reloading can be significantly increased, which is especially important when transshipping grain in ports. For transshipment of grain in a port or other place, you can also use a grain loader with an innovative hopper PZM-120B2 .

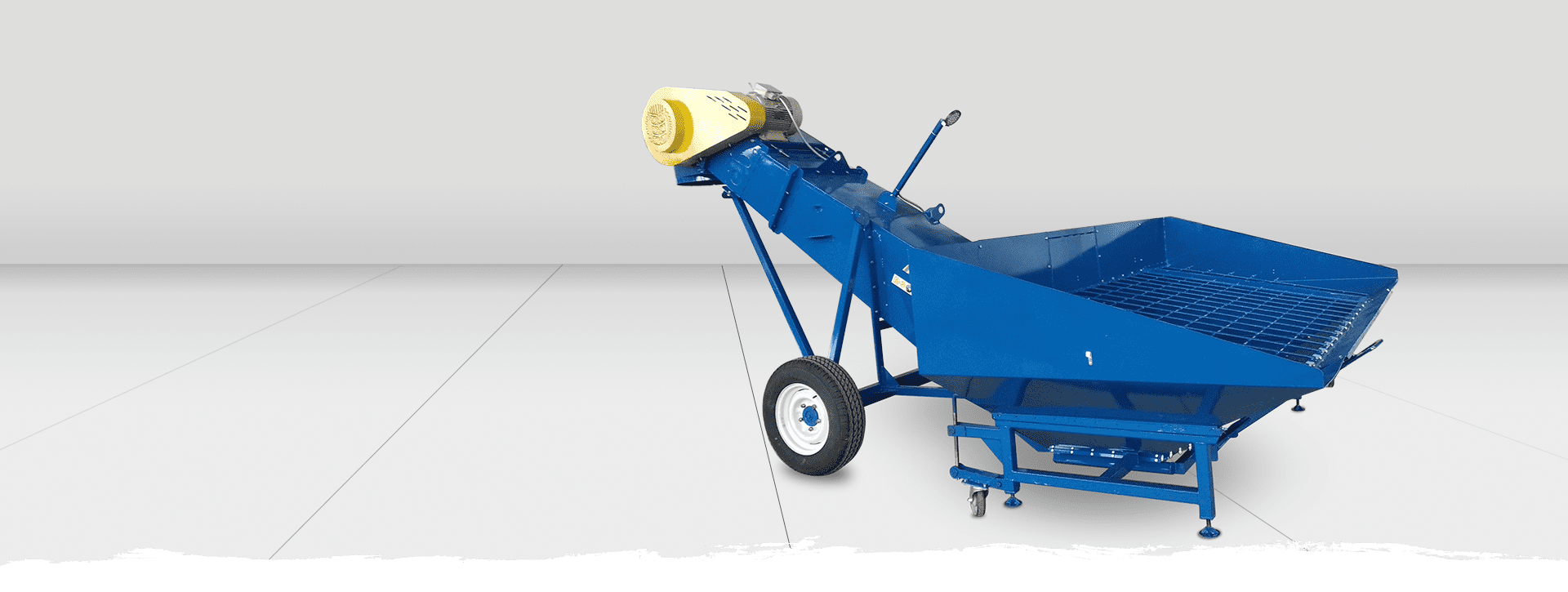

The PZM-170P mobile grain handler consists of a bunker and a scraper conveyor mounted on a powerful frame with 4 wheels, additional height-adjustable supports, an electric motor, a towing device and a control panel.

The design of the PZM-170P portable grain handler also includes:

- 2 spotlights adjustable in height and directed forward and backward, which allows you to reload the grain in the dark;

- an awning that completely covers the hopper and protects it from foreign objects and rain;

- a grate that prevents large objects from getting into the hopper and further into the reloaded grain;

- additional height-adjustable wheels, jack and hitch that allow you to easily move the portable grain loader to the desired location.

The use of the PZM-170P portable grain handler allows you to save on the construction of stationary grain cleaning complexes, speed up and make more efficient the process of loading ships, barges, wagons, silos, augers, big bags, etc. several times and has many other advantages. The price of a portable grain loader is much lower than the price of stationary loaders.

| Loader type | mobile |

| Performance, tons per hour | up to 200 |

| Grain loading height, m | up to 1,7 (adjustable) |

| Width in working position, m | 3 |

| Width in transport position, m | 2,05 |

| Height, m | 2,37 |

| Length, m | 4,95 |

| Ground clearance, m | 0,25 |

| Type of drive | electric |

| Capacity, kWt | 7,5 |

| Electricity consumption, kWh per t | 0,04 |

| Lighting | 2 spotlights |

| Weight, kg | 870 |

Ways to use a portable grain loader with a hopper and conveyor PZM-170P:

- A portable grain loader is located near grain cleaning complexes and provides grain supply from grain carriers to bucket elevators, augers and other transport equipment.

- A portable grain loader can be installed near silos or in a granary, in an open area, etc., where it will load grain into augers and similar equipment that does not have a large receiving hopper.

- The portable grain loader PZM-170P is installed in the port directly on the berth near the moored vessel. At the same time, the PZM-170P loading elevator turns towards the vessel. The mobile pit hopper is located in the opposite direction and accepts grain, seeds, granules and other bulk cargo from any transport. At the same time, the side of the vessel must be below the neck of the PZM-170P conveyor.

- If the vessel is at a considerable distance from the berth, the PZM-120B2 grain thrower with an innovative hopper or a grain belt loader together with a portable grain loader can be used. In this case, a portable grain loader is installed so that its hopper is located directly to the approaching transport, and the neck of its conveyor is above the hopper or loader belt.

- Depending on the performance of existing equipment, the number of portable grain handlers working with it can vary and they can be installed in a variety of ways. For example, the productivity of a grain belt loader is 630 tons per hour and it has 1 receiving hopper, into which grain is loaded from 1 grain truck. The performance of this loader is limited by the number of grain carriers that pour grain into its bunker and does not exceed 230 tons per hour. To increase productivity by 3 times, 2 portable grain loaders PZM-170P are installed on the sides of the port loader. As a result, the loading of grain into the ship increases to 630 tons per hour and the port belt loader works with the required capacity.

- During operation, the performance of a portable grain loader can be adjusted by changing the position of the metering valve located in its hopper.

- The portable grain loader PZM-170P can be additionally equipped with a chute that rotates in different directions and rises up and down. Thanks to this chute, the range of grain reloading can be significantly increased, which is very popular when transshipping grain in ports.

The main advantages of a portable grain handler with a hopper and conveyor PZM-170P:

- This is the easiest and cheapest way to quickly reload grain, seeds in an open area, in a grain warehouse and transfer bulk cargo to ships, barges, etc. directly from a truck.

- Versatility - can handle grain, seeds, granules, pellets and other bulk cargo.

- The mobile grain handler is perfectly combined with any loaders and provides a continuous process of loading grain cleaning complexes, grain warehouses, ships, etc.

- Thanks to a very simple and reliable design with a hopper directly located to the conveyor of a portable grain loader PZM-170P, the speed of loading grain into barges, wagons, silos, grain cleaning complexes, etc. increases several times, and the process itself is also simplified at times.

- Fast payback, including by reducing the idle time of grain trucks and other vehicles in the queue for unloading and reducing the overall energy consumption due to the operation of existing equipment at full capacity.

- Profitability - electricity consumption for receiving and reloading 1 ton of grain is 40 W.

- The grain loading speed can be adjusted and coordinated with the speed of transport and other equipment.

- High productivity - up to 200 tons per hour, depending on the type of loaded grain, granules or pellets and the technology of using a portable grain loader.

- Innovative, simple and reliable design using high quality components from the best European manufacturers.

- Possibility to install a frequency converter for gentle handling of a small amount of seeds or fertilizers and matching the loading speed with the capabilities of other equipment.

- The presence of a quick-release awning that completely covers the hopper of the PZM-170P mobile grain handler and protects it from foreign objects, rain, snow, etc.

- The presence of a grid that prevents large items from getting into the hopper of the reloader and further into the reloaded grain.

- The presence of 2 headlights - searchlights with adjustable tilt angle, which allows you to reload the grain in conditions of insufficient visibility.

- The PZM-170P grain loader hopper is equipped with additional height-adjustable wheels, a jack and a drawbar, which allow it to be easily transported to the right place.

- Easy access to working units, simple and convenient operation and maintenance by 1 person of low qualification.

- An overload prevention system during operation and a 24-volt control panel, which eliminates risks for personnel.

Video of how a portable

grain handler works in the port