The grain mix, obtained after harvesting, consists of seeds of different plants and contains impurities of mineral and organic origin. The extent of purification of grain considerably influences its price, productivity and quality of grain at storage.

Allocation of seeds of the main culture in a pure shape is one of the major and labor-consuming technology transactions in the processes of acceptance, storage and processing of grain. In many countries, in the structure of cost price of grain up to 40% falls on postharvest processing, and labour inputs reach 50% of total costs.

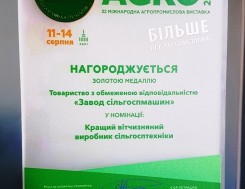

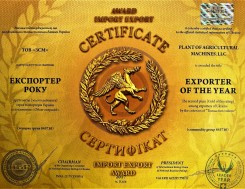

Application of our innovative mobile machines allows quickly moving to a new level of usage of equipment and technologies, reducing costs and a payback period of agricultural machinery by several times, and also considerably increasing the profitability of cultivation of agricultural products.

Our innovations in postharvest processing of grain are protected by patents and implemented in constructions of mobile grain-cleaning complexes, self-propelled grain-cleaning machines and grain-throwers.

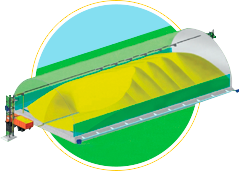

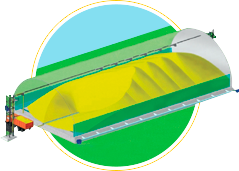

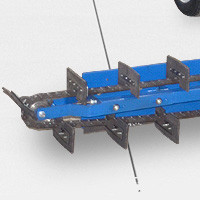

The self-propelled grain-cleaning ОВС-70М4, OВС-70М4L complexes and their modifications ARE INTENDED FOR ACCOMPLISHMENT OF THE FOLLOWING TECHNOLOGY TRANSACTIONS

THE INNOVATIVE SOLUTIONS OF THE CONSTRUCTION of self-propelled grain-cleaning ОВС-70М, ОВС-70МП complexes and their modifications ARE AS FOLLOWS:

INNOVATIVE SOLUTIONS OF THE CONSTRUCTION of the ОВС-50Ш mobile grain-cleaning complex ARE AS FOLLOWS:

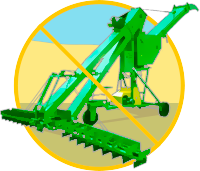

INNOVATIVE SOLUTIONS OF THE CONSTRUCTION of self-propelled cleaners of heaps ОВС-25Ц with a cyclone, ОВС-25Д with additional system of cleaning and their modifications are as follows:

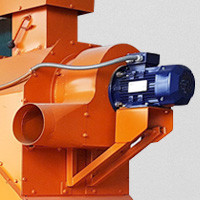

The Grain-throwers ПЗМ-120М, ПЗМ-170 and their modifications

THE INNOVATIVE SOLUTIONS OF THE CONSTRUCTION of grain-throwers ПЗМ-120М, ПЗМ-170 and their modifications ARE AS FOLLOWS:

It is not necessary to spend a lot of time for the process of cleaning and shipping of the grain. The innovative equipment of the Plant saves 40% expenditure of time for processing.

It is reached due to big efficiency, a minimal cost of processing of grain, state compensation for expenses for purchase, and excellent quality.

One innovative mobile machine replaces the whole complex of machines on postharvest grain processing.

Learn in detail about us and our products, make an appointment to visit the plant or ask a question – all these can be done by phone or a feedback form.

Fill in your data and we will definitely answer you!