The Grain Cleaning Machinery Plant is manufacturing fixed grain cleaning machines of different modifications capable to carry out effective cleaning of a heap of chaff and grain of the impurities and perform grain grading.

The grain cleaning machines are capable to release grain from, dust, trash as well as to separate crushed grain. The grain cleaning unit is used for separation of grain, cereal, oil, leguminous, and other agricultural crops.

The grain cleaning and grading units are used either independently or in the fixed production line of grain cleaning complexes.

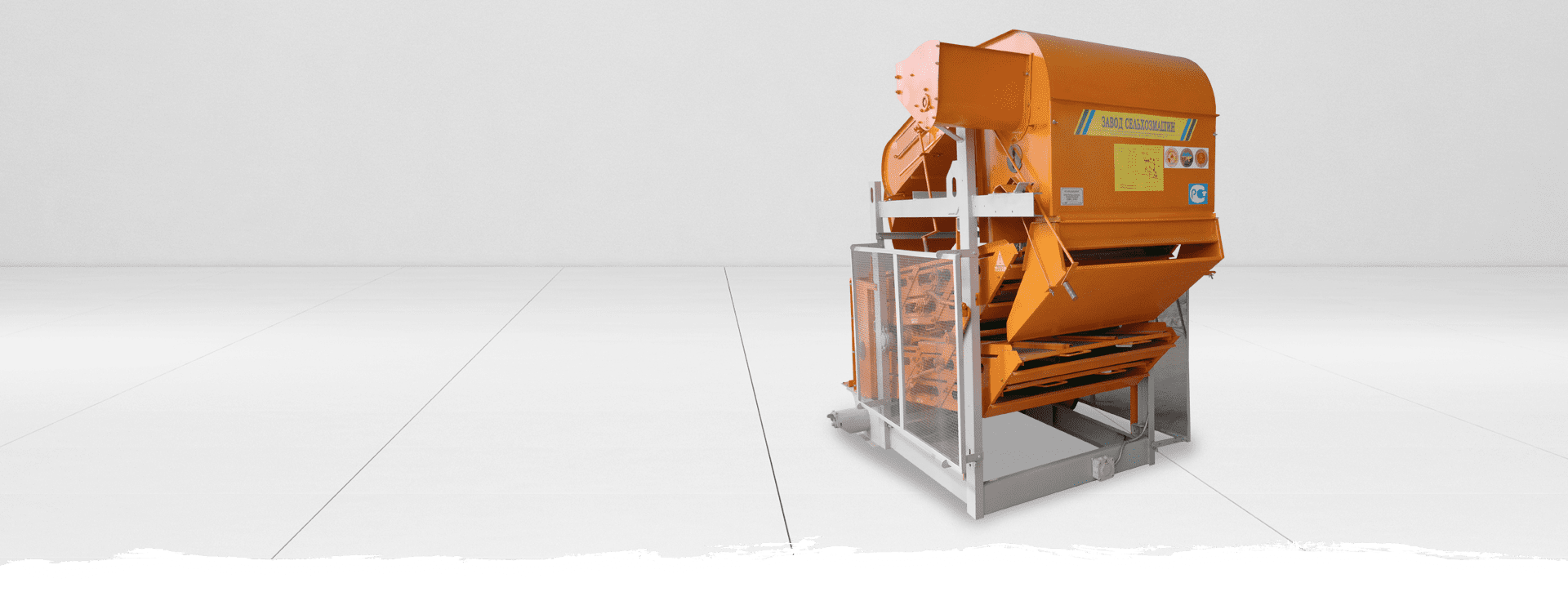

Stationary

grain cleaning

machines

A heap of chaff and grain is cleaned and assorted the most effectively, if a design of grain cleaning machine combines two methods of grain cleaning:

- by aerodynamic properties using the ascending air

- by size using the screens or screen feeder

When using our fixed grain cleaning unit, the effective grain sorting takes place due to an excellent combination of these two methods in its design.

The airflow, which power is regulated in dependence on the type and variety of the grain being cleaned, passes through the grain. Consequently, the light impurities are caught and deposited in the air system of a grain cleaning unit.

The screens or screen feeder with different screen sizes are used to clean grain of the heavy, coarse, and fine impurities as well as to separate it by size. Three types of screens with round, slotted, and triangular holes are used in the grain cleaning machines of our manufacture.

The screens are put into the metal frames being fastened in the screen shoes in two tiers.

In the grain cleaning machine ЗВС-20А, the coarse impurities (particles of stalks, coarse trash, etc.) are isolated from the heap of chaff and grain on the screens of the first tier. The fine impurities are isolated and removed from the machine on the first screens of the second tier with the seeds being separated according to their size in two varieties on the following sorting screens. The precise grain grading takes place in such a way.

Quality grain separation may be also carried out with the use of other fixed grain cleaning machine OВС-25С. The models are outfitted with a brush cleaner, which is important when the grain cleaning and sorting inasmuch as this makes it possible efficiently clean the grain of impurities and the screens of stuck particles.

A cyclone is successfully integrated into the grain cleaning machine ОВС-25СЦ . The problem connected with cleaning of the air of dust and light impurities is compactly solved by virtue of such updating.

The grain cleaning machine OВС-2С characterized by compact sizes and high-quality grain cleaning will be excellently suitable for small farm enterprises. The grain cleaning machine МПО-50М will be excellently suitable for the grain cleaning lines of medium-sized and large-scale farm enterprises.

The fixed grain cleaning units are manufactured by the Agricultural Machinery Plant with the use of the state-of-the-art machinery and technologies, that is the complexes of laser-beam cutting, high-precision bending, balancing, welding, and CNC machines. All the above mentioned as well as the active research work make it possible for us to manufacture the assemblies of the highest possible standard being distinguished by reliability and performing high-accuracy grain cleaning and separation.

The innovative machinery and equipment of the Agricultural Machinery Plant is reliable, high-technology, ergonomic, and environmentally friendly. Its excellent quality and performance capability gain deserved recognition in the specific contests and exhibitions. Our fixed grain cleaning machinery won the Grand Prix of the Quality Mark “The Highest Quality” the National Quality Award and earned an award “The Best Products of the Year”. The Agricultural Machinery Plant was rendered the best manufacturer of the agricultural machinery for six years in succession being awarded the gold medals at the exhibitions AGRO-2013 – 2018.

The advantages of all fixed grain cleaning machines manufactured at our Plant are as follows:

- high quality of grain and seed cleaning

- simple and reliable design

- quick setting for any type of grain and seeds

- superior quality

- minimum electric power consumption

- short payback period

The use of fixed grain cleaning assemblies is a good way to carry out cleaning and sorting of a heap of chaff and grain, which will be suitable for the large-scale, medium-sized, and small farm enterprises.

The agricultural machinery of our manufacture has already been recognized in many countries. Contact us, and you will receive high-performance agricultural machinery for grain cleaning, which price is reasonable.

Outfit your farm enterprise with the state-of-the-art machinery, which will help you to carry out quality cleaning and sorting of grain within a short time.