The 3BC-20A primary grain cleaning machine is easy to use and perfectly fulfills the functions assigned to it to remove debris from grain material.

3BC-20A performs the following functions:

- Eliminates dust and light trash using a powerful integrated suction system.

- Using 16 sieves installed in the machine, it carries out high-quality cleaning of grain heaps from large and small debris, chopped grain and separates the grain into fractions.

3BC-20A is a reliable and popular grain cleaning machine, which is successfully used for cleaning grain heaps of cereals, ears, legumes, oilseeds, corn, sunflower, sorghum, rape, coriander and many other crops. With the help of 3BC-20A, even very contaminated grain can be effectively cleaned to produce a quality product.

3BC-20A is a universal grain cleaning machine that can operate in three modes:

- in pre-treatment of grain with a capacity of up to 50 tons per hour;

- in primary grain cleaning mode with a capacity of up to 25 tons per hour;

- in the calibration mode of grain for seeds with a productivity of up to 12,5 tons per hour.

The 3BC-20A primary grain cleaning machine was improved by the agricultural machinery factory taking into account the modern needs of the agricultural sector. Its use will quickly and efficiently eliminate unnecessary impurities from the grain material and obtain high-quality grain.

| Productivity, tons per hour | 12,5 - 50 depending on the operating mode and grain |

| Type of machine | stationary |

| Type of drive | electric |

| Width, m | 2,03 |

| Height in working condition, m | 2,75 |

| Length, m | 3,07 |

| Mass, kg | 1805 |

| Height in transport position, m | 2,65 |

| The number of sieves, pieces | 16 |

| Sieve Size, mm | 740х990 |

| Grain crushing, not more than,% | 0.2 |

| Installed power, kW | 7.7 |

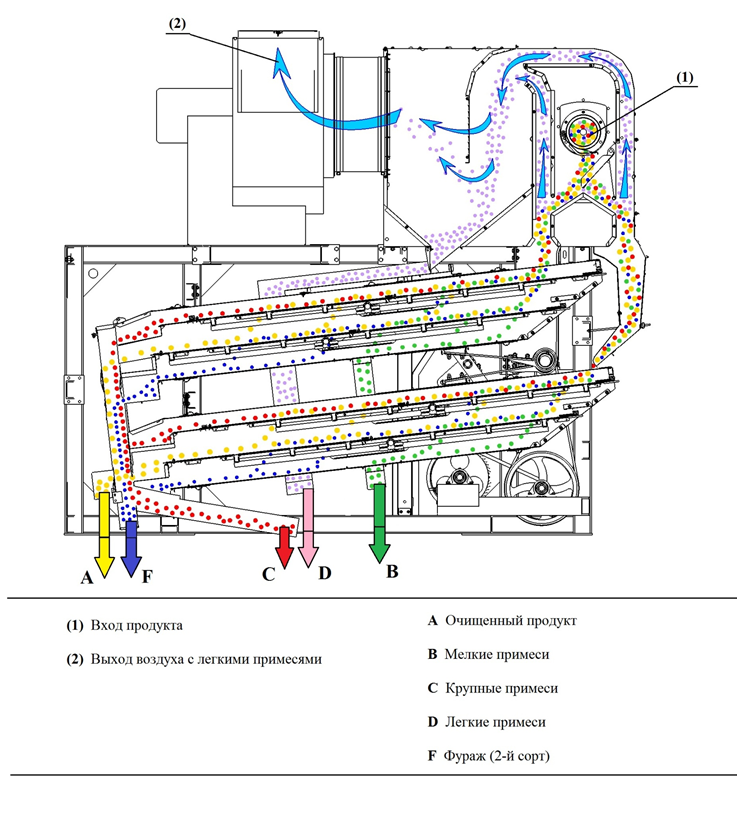

3BC-20A grain cleaner working scheme

Cleaning grain using 3BC-20A is as follows. The grain enters the receiving part of the machine, after which the screw distributes it across the entire width of the air chamber. The grain material is cleaned using a stream of air that blows light debris from the grain heap and sends it to the settling chamber.

Then comes the second stage of grain cleaning using sieve mills. The grain is divided into two equal parts and distributed between simultaneously working upper and lower mills.

At 3BC-20A, two planes of sieves are installed in each mill. The first plane allows you to save the grain material from large impurities that remain on the sieve, while the grain is sieved through large cells below. The second plane leaves grain on the surface, and small impurities and crushed grains fall through the cells below. Such cleaning with the correct selection of sieves gives a very good result and high-quality refined grain comes from the lower sieve of each mill.

Advantages of the 3BC-20A grain cleaning machine

3BC-20A is a universal reliable grain cleaning machine that can operate in three modes - preliminary, primary and secondary cleaning. The use of this improved model as part of grain processing complexes and lines allows efficient grain cleaning even with significant contamination and to obtain a high-quality product.

3BC-20A is reliable and easy to maintain, it will work for a long time and will provide you with high-quality cleaning of the grain heap.

3BC-20A is popular in many countries and successfully replaces grain cleaning machines from other manufacturers.

At the largest exhibition in Eastern Europe, AGRO-2013 ЗВС-20A was awarded with a diploma of the winner as the best grain cleaning machine.

Watch the video how the grain cleaner works