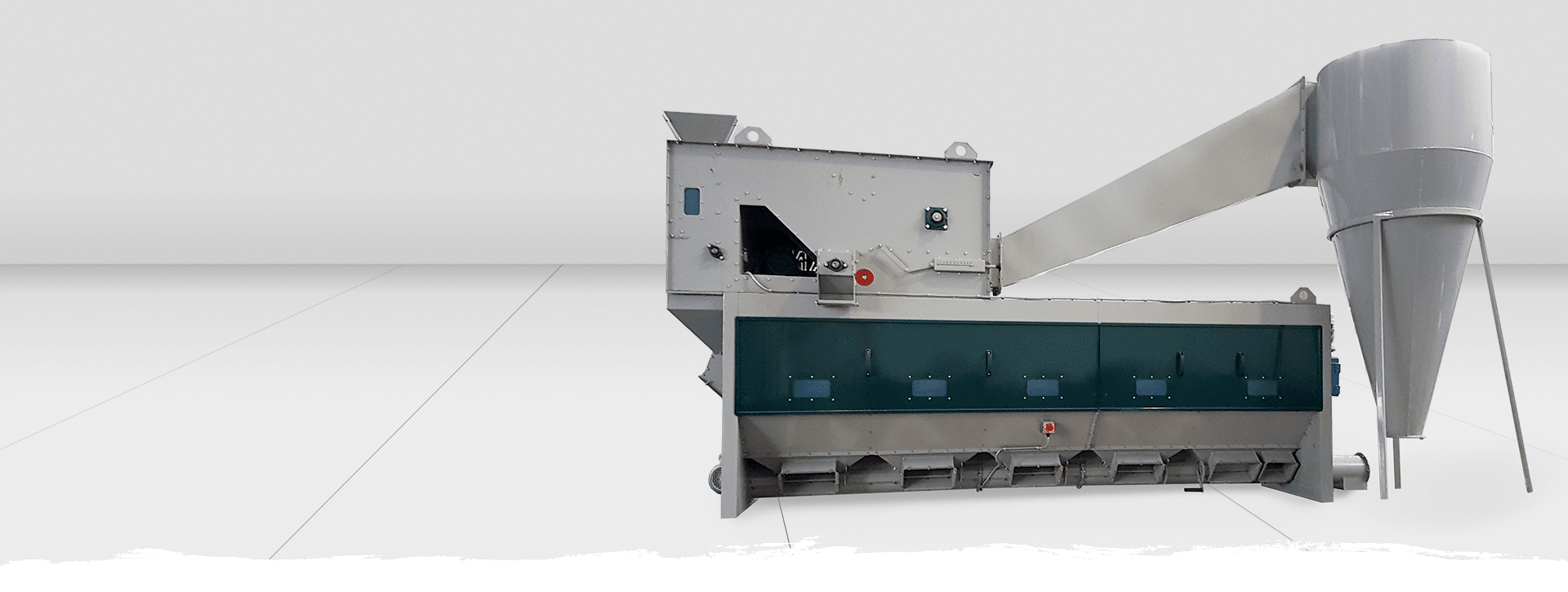

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds and additionally equipped with a cyclone. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit.

The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct.

Cleaning and calibration of grain and seeds is first carried out by aerodynamic properties with controlled air flow, which removes those impurities that are lighter than grain. Then the grain cleared of light impurities is poured onto the sieve part of the drum separator, which consists of 5 sieves installed in series. The sieves are used for cleaning and sizing seeds. The sieve openings are automatically and efficiently cleaned by the brush and roller system installed in the separator.

Seed separator with cyclone OVS-355Ts is successfully used for sorting and calibration of various products (for example: a mixture of any grain and impurities, grain with a large amount of garbage and impurities, corn grains with high moisture content, fibers and cotton seeds, balls, etc.).

1 and the same grain-cleaning separator with cyclone OBC-355C can be used both for high-quality calibration and for preliminary cleaning of large amounts of grain and seeds.

Grain separators OBC-355C have the following main advantages:

- Maximum versatility in application.

- Greater cleaning efficiency.

- High accuracy of grain calibration by aerodynamic properties, width and thickness.

- Minimal vibration during operation.

- Fast replacement of sieves.

- Gentle handling of seeds and grain.

- Adjustable performance.

- The presence of a cyclone that traps dust and light impurities.

For more details about the advantages of the OBC-355C seed separator, see the "Advantages" section.

The universal multifunctional separator OBC-355C with a cyclone is an excellent choice for farms growing all types of seeds and grain.

| Performance, t/h | up to 35 |

| Capacity, kw | 4,4 |

| The number of installed sieves, pieces | 5 |

| Mass, kg | 1210 |

| Length, m | 5 |

| Width, m | 1,6 |

| Height, m | 2,31 |

Scheme of operation of the OBC-355C universal seed separator in the mode of cleaning and separating rapeseed, wheat and pea grains.

There are more than 50 operating schemes for the OBC-355C grain separator.

A - loading raw heap

B - external air flow

C - grain unloading without cleaning with a separator (cleaning from light impurities)

D - unloading of small heavy impurities

E - unloading of a small fraction of the product (for example, rapeseed, millet)

F - unloading beaten grain, halves

G - unloading of the middle fraction of the product (e.g. wheat, barley)

H - unloading a large fraction of the product (e.g. peas, soybeans)

I - unloading of large waste

J - unloading through auger

K - unloading auger of light waste

L - air with dust and light impurities

М - dust and light impurities

N – air

Advantages of the universal drum separator for grain and seeds ОВС-355С:

1. Multifunctionality and versatility

Universal grain cleaners cancan be used both for high-quality calibration and for preliminary cleaning or separation of grain and seeds from three crops at once. More than 50 variants of operation are possible.

2. The presence of a cyclone that cleans the air from the aspiration system from dust and light impurities.

3. Cleaning efficiency

The efficiency of the process of cleaning and removing small impurities and crushed grain through the holes on the screens is very important. On drum grain cleaners OBC-355 type, the sieves are cleaned in the upper part,where there is no grain. In this case, both brushesand wooden rollers are used for cleaning, which increases the efficiency of cleaning the sieves.

4. Calibration accuracy

Constant movement and absence of vibrations allows each grain or particle to enter more easily into the holes on the sieves. That is why drum seed cleaners are often used for accurate calibration.

5. Flexibility of operation

In grain cleaners OBC-355C type, each sieve can be used to remove different or identical grains and impurities. The operation of the separator changes rapidly depending on the needs. During calibration, the number of sieves determines the maximum number of fractions into which the grain can be divided.

6. Adjustable rotation speed and inclination of the drum with sieves

In any flat screen cleaner, an increase in speed and tilt will result in grain bouncing and reduced sorting accuracy. In grain cleaners OBC-355 type, changing the speed and tilt improves the calibration accuracy and increases productivity. This provides more application possibilities.

7. Gentle handling of grain and seeds

In the process of cleaning and separation, seeds and grain move along grain separator OBC-355 type by gravity, which eliminates its damage.

8. Application for products that are difficult to sort

Grain cleaners OBC-355C are used for separation and calibration of a wide range of products (for example: fibers and cotton seeds, corn grains with high moisture content, balls, etc.). It can be used for both high quality calibration and precleaning of any grain and seed.

9. Quick replacement of sieves

Thanks to the devices specially installed on each sieve, the process of replacing all 5 sieves in grain cleaners OBC-355 type is carried out in less than 5 minutes. Quick replacement of sieves saves time, speeds up the process of grain cleaning and seed calibration.

Watch the video how the separator works

See how quickly the sieves change