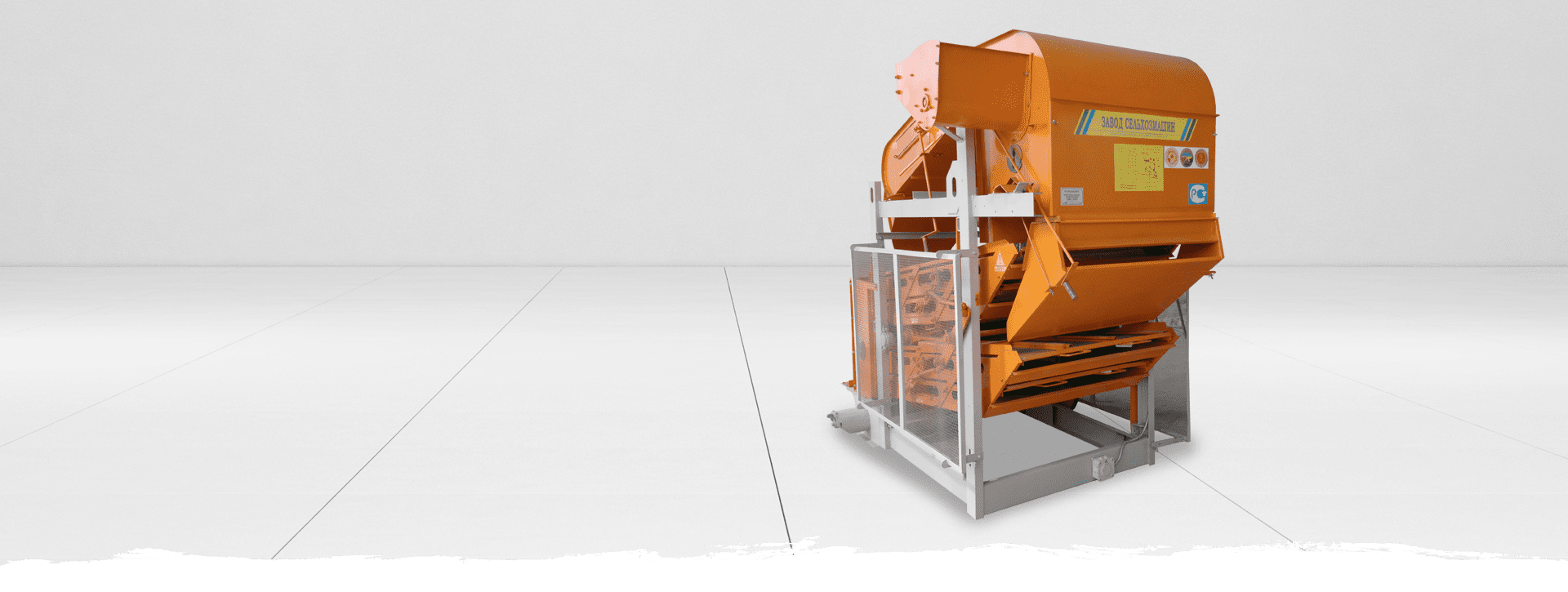

Stationary grain cleaner OBC-25S performs the initial cleaning of cereals, ears, legumes, sunflower, sorghum, rapeseed, corn, etc. Heap cleaner is installed in existing grain cleaning units or mounted separately.

OBC-25S is equipped with a receiving chamber, an air-cleaning part, sieves, a feed waste screw. All working bodies are mounted on the frame.

The main difference between the OBC-25S and aerodynamic separators is the cleaning of crops not only by air flow, but also by brushes and sieves.

OBC-25S performs the primary cleaning of grain and seeds using an aspiration system and sieves. The distributor divides the grain with impurities into two equal parts and directs it to the air channels. Airflow through the fan carries off light impurities. Larger impurities from the air stream are captured by the settling chamber.

Further, the grain purified by the aspiration system falls on the upper and lower sieve mills. On sieves, the process of cleaning grain from impurities that differ from grain in size occurs. The sieves are cleaned with brushes.

Pure grain is collected at the bottom of the OBC-25S and poured into a hopper or other container (not included in the package).

OBC-25S is a reliable and highly efficient grain cleaning machine.

If necessary, the OBC-25CS grain cleaner can be additionally equipped with loading and unloading elevators, as well as a cyclone. At the request of the customer, wheels can be installed on the OBC-25S, which turns this car from a stationary to a mobile one.

The scheme of work of a stationary grain cleaner OBC-25S:

- Grain material is noria fed into the distribution screw of the grain cleaning machine’s feed device. Further, the feed device distributes the grain across the width of the chamber. The distributor divides the material into two equal parts and sends it to the air channels.

- Light impurities are separated by an air stream and carried away into a centralized air system.

- Impurities that are larger are collected from the air stream by a settling chamber.

- Grain that has been cleaned by air flow is divided into two equal parts and enters the upper and lower sieves. Cleaning on the upper and lower sieves is the same.

- Finished clean grain is fed to the rear receiver. From the receiver, the grain is fed by a screw to the conveyor.

| Productivity, tons per hour | up to 25 |

| Electric motor power, kW | 4 |

| The number of installed sieves, pieces | 8 |

| Weight kg | 1010 |

| Length, m | 2,86 |

| Width, m | 1,76 |

| Height, m | 2,50 |

Watch a video about the OBC-25S