The MPO-50M machine carries out quick preliminary cleaning of grain, legumes, oilseeds and industrial crops, corn, sorghum, rapeseed, sunflower seeds, grasses, etc.. Designed to function as part of stationary production lines of grain cleaning complexes. Also, MPO-50M is often installed immediately before drying.

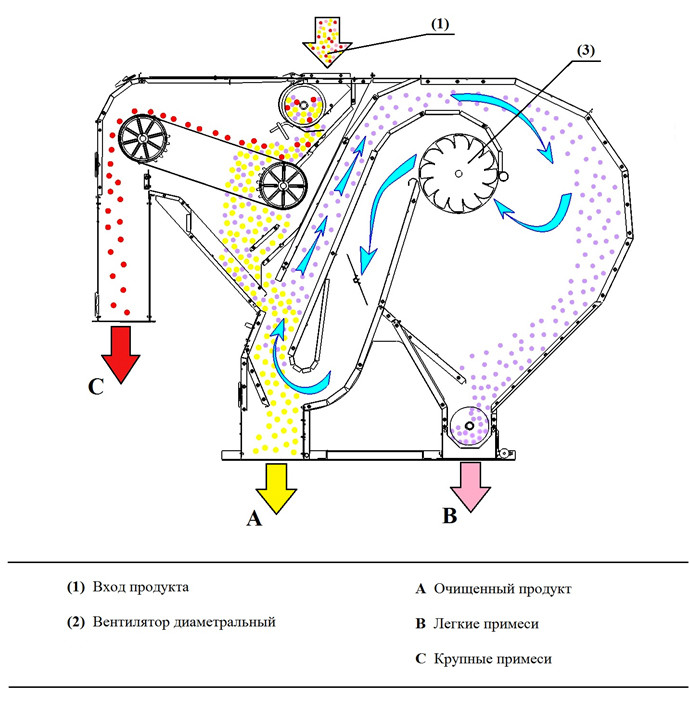

Preliminary cleaning of grain in MPO-50M is carried out according to two main parameters - size and aerodynamic properties (see the scheme of work).

The advantages of MPO-50M are that it is a universal high-performance machine for quick pre-cleaning of any grain or seeds of any moisture content. MPO-50M can easily cope even with cleaning grain that is very wet and clogged with straw and other impurities.

High speed of operation increases production volumes per unit time and allows you to quickly move from the stage of preliminary preparation of raw materials to the next stage in order to better preserve seeds and grain, prepare them for drying and active ventilation, increase the efficiency of subsequent cleaning.

Buying a grain pre-cleaning machine MPO-50M is an excellent solution for increasing the efficiency of any grain cleaning or grain drying complex.

| Productivity, t / h | up to 70 |

| Drive | electric |

| Mass, kg | 1041 |

| Total power, kW | 6,05 |

| Dimensions in working position: | |

| Height (adjustable), m | 2,5 |

| Length, m | 2,85 |

| Width, m | 1,85 |

Scheme of operation of the grain pre-cleaning machine MPO-50M:

- grain through grain pipelines enters the receiving chamber MPO-50M, from which it enters the mesh conveyor in an even layer;

- grain passes through a mesh conveyor, separating from large impurities. The size of the conveyor cell is from 4 to 19 mm;

- large impurities in the conveyor fall into the hopper, from where they are removed from the machine down;

- the mesh conveyor is shaken regularly to ensure intensification of grain cleaning;

- grain after passing through a mesh conveyor is divided into two streams and enters the pneumatic separation channel;

- the air flow created by the fan passes through the grain flow, picking up light impurities. The power of the air flow is adjustable. This is the most effective way to remove light impurities;

- in the sedimentary chamber, light impurities are separated from the air flow due to centrifugal force. Clean air enters the fan again, and light impurities are removed from the grain pre-cleaning machine MPO-50M;

- pure grain is unloaded from the grain pre-cleaning machine MPO-50M by gravity through a special valve.

Advantages of the MPO-50M grain pre-cleaning machine:

- MPO-50M is a modern modified machine that provides quick preliminary cleaning of any grain and seeds of any moisture content.

- The MPO-50M pre-cleaning machine can easily cope with cleaning even grain and seeds heavily clogged with straw and other impurities.

- This high-performance machine will help clean large volumes of grain in a short time in order to better preserve seeds and grain, prepare them for drying and active aeration, and increase the efficiency of subsequent cleaning.

- Minimum electricity consumption - 0.08 kWh for cleaning 1 ton of grain.

- Simple, reliable design.

- Small dimensions and weight.

- Possibility of quick installation in any grain cleaning lines and before dryers.