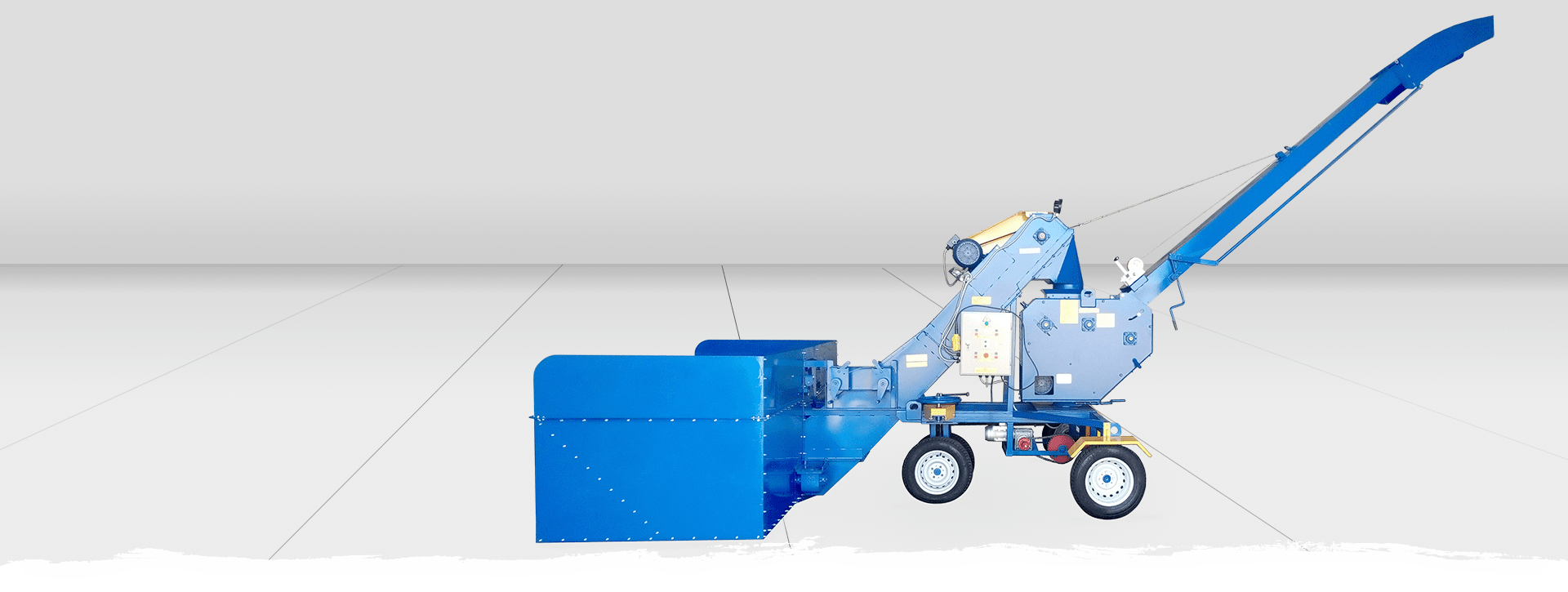

Self-propelled grain loader with a large hopper PZM-170B is intended for unloading grain from grain carriers and trailers directly into the bunker of this grain thrower and subsequent loading of granaries to a height of up to 9 meters. Grain loader PZM-170B is also successfully used for loading grain carriers, trailers, wagons, containers and trucks.

Unlike the PZM-170 grain thrower, the PZM-170B grain loader has a hopper instead of scraper feeders. The size of the hopper is 3.12 meters wide, 1 meter high with a lowered front wall, and a volume of about 4 cubic meters. It is convenient when handling grain in ports, grain warehouses and other premises, or in open areas.

Self-propelled grain loader with a large hopper PZM-170B is used in the following sequence:

- grain loader PZM-170B drives up to the loading point on its own;

- the hopper is lowered into the working position and rests on the surface of the warehouse;

- a car, a loader or a tractor with grain drives up to the hopper;

- grain from a car, trailer or bucket is poured into the PZM-170B hopper;

- the loader transporter loads the grain from the hopper into the trimmer, which throws it through a special guide pipe to a height of up to 9 meters and up to 25 meters in length;

- the trimmer with the pipe can be easily rotated 257 degrees. The process of changing the height or direction of flight of grain takes no more than 3 seconds;

- the grain escaping from the trimmer pipe is sent to a truck, trailer, grain barn, wagon, container, etc. or it is stored in piles up to 9 meters high.

The process of using a grain loader with a hopper in warehouses with centralized loading and unloading of grain is similar. The only difference is that the grain is poured into the hopper of the PZM-170B loader from the hopper of the centralized loading or unloading of the granary.

The productivity of PZM-170B is up to 170 tons of grain per hour.

Buying a self-propelled grain loader with a PZM-170B hopper is an excellent solution if you are a grain trader, a farm or are engaged in transshipment and shipment of grain in large volumes.

| Capacity, tons per hour | up to 170 |

| Hopper width, m | 3,12 |

| Hopper height, m | 0.9-1.1 (front lower) |

| Hopper length, m | 1,27 |

| Hopper volume, cubic meters | 4 |

| Total installed power, kW | 13,55 |

| Range of grain flight, m | Up to 25 (adjustable) |

| Grain flight height, m | Up to 9 (adjustable) |

| Weight, kg | 1250 |

| Height in working position, m | 3.05 - 4.50 (adjustable) |

| Length in working position, m | 4.25 - 7.0 (adjustable) |

| Lighting forward and backward | available |

| Remote control | available |

The PZM-170B self-propelled grain loader with hopper has the following main advantages

- Big hopper with the width of 3,12 m, where the grain is unloaded from a grain carrier, trailer or other transport;

- Grain loader is self-propelled;

- Grain flight distance reaches 25 meters;

- Excellent productivity - up to 170 tons of grain per hour;

- High loading height of warehouses and transport - up to 9 meters;

- In the process of operation of the grain loader there is a partial separation of the light impurities and the humidity of the grain is reduced to 2% at a time;

- Grain loader with a hopper consumes only 0.1 kW of electricity for loading or transportation of 1 ton of grain;

- Ergonomic, simple and reliable design, which meets the standards of the European Union;

- Change of direction, range or height of grain loading takes not more than 3 seconds;

- Easy and convenient operation and maintenance;

- Possibility to adjust productivity by changing the position of special flaps in the hopper of the grain loader.

Watch the video