Loader ZZ-120 loads any kind of grain, granules, sunflower meal, pellets, etc. in any wagons and containers. Loader capacity up to 120 tons per hour. The flight range of the grain is up to 20 meters, the height is up to 9 meters and is regulated in 1 second. Grain loader ZZ-120 can rotate around 360 degrees. This allows you to load grain and other bulk cargo into wagons and containers of any length and height.

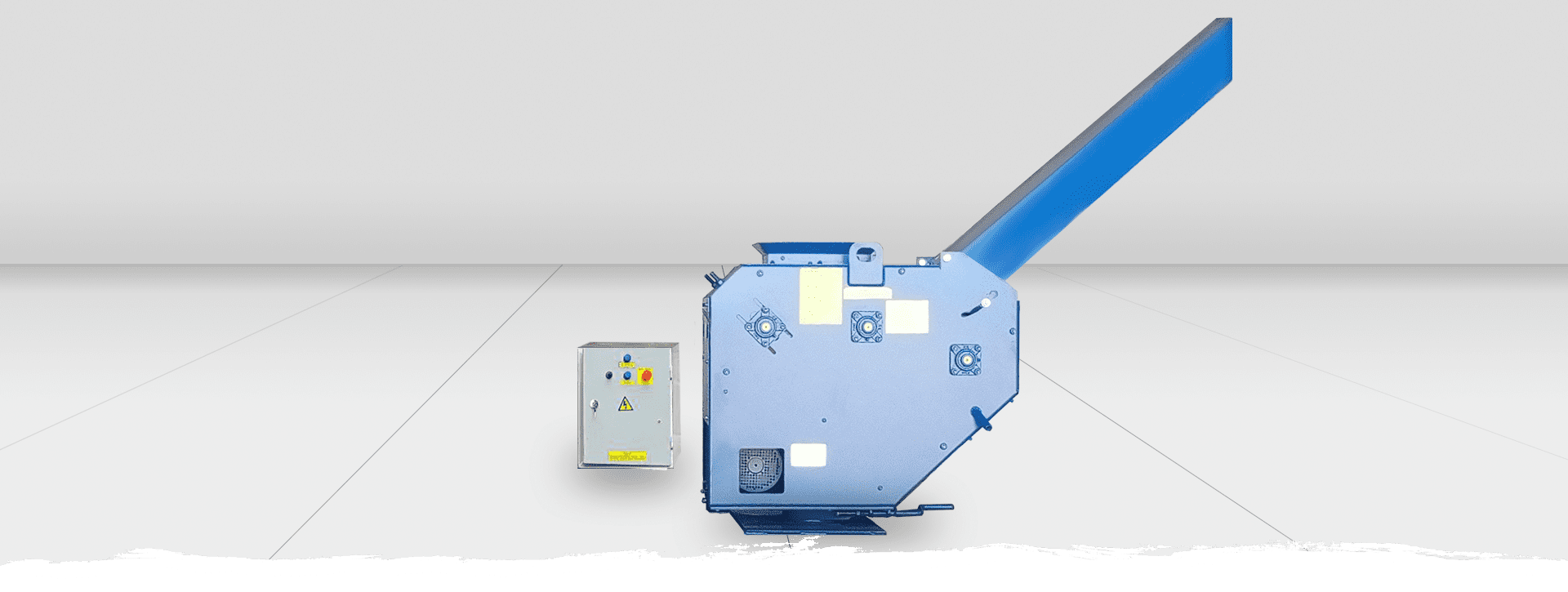

The ZZ-120 grain loader consists of a trimmer with a support and an electric motor, a special trimmer pipe and a control panel. Electricity consumption for loading 1 ton of grain is only 0.046 kWh. A frequency converter can be additionally mounted in the control panel, which provides additional opportunities for regulating the range and height of the flight of grain.

Unlike the FulFiller container loading system, there is no need to hook the ZZ-120 grain loader directly onto the container itself using a forklift. The ZZ-120 wagon and container loader is usually mounted on a support mounted on a warehouse or elevator column. This means that the use of the ZZ-120 wagon loader is many times easier and cheaper than the FulFiller loading system.

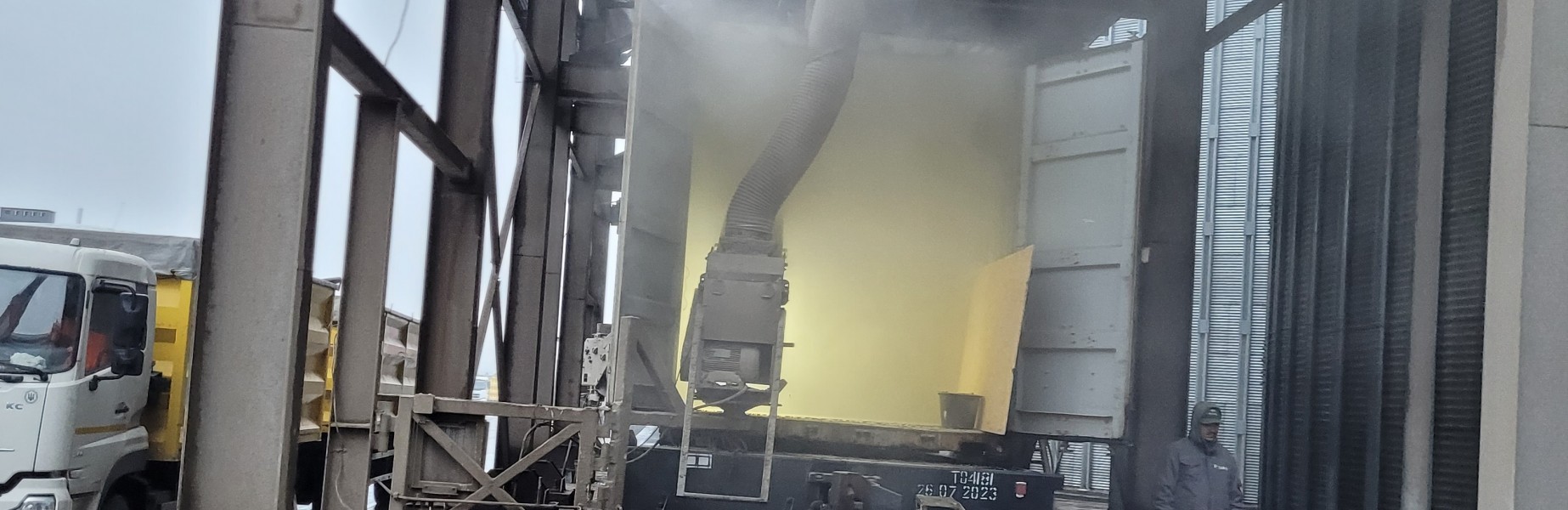

ZZ-120 is successfully used for loading containers on trucks and railway platforms. Also, using the 33-120 loader, you can load trucks with grain at grain storage facilities.

The ZZ-120 grain loader is an excellent system for fast loading of grain into railway cars and containers at elevators and grain warehouses.

| Productivity, tons per hour | up to 120 |

| Grain flight height, m | up to 9 (adjustable) |

| Range of grain flight, m | up to 20 (adjustable) |

| Total installed power, kW | 5,5 |

| Weight, kg | up to 297 |

| Mains voltage, volts | 220-390 |

| Electricity consumption for loading 1 tonne of grain, kWh | 0,046 |

The main part of the ZZ-120 grain loader is the PZM-120 grain thrower trimmer

The trimmer is equipped with the following supplied:

- loading funnel through which the grain enters the trimmer;

- a special pipe through which the grain is unloaded from the trimmer into the container.

The trimmer is mounted on a special base plate with a brake to fix the position of the trimmer (included). The base plate has a special design that allows the trimmer to rotate 360 degrees.

The trimmer base plate is mounted on a metal column or any suitable fixture directly at the customer's site.

Grain from the storage hopper enters the trimmer feed funnel. The trimmer ejects grain or other bulk material into the container through a special pipe.

In 1 second, by changing the position of the trimmer pipe and (or) the trimmer, the worker can change the direction and height of grain loading into a container or wagon.

The ZZ-120 container loader is turned on and off from the control panel (included in the delivery set), which is mounted next to the loader.

The main advantages of the grain loader in containers ZZ-120:

- high productivity - up to 120 tons per hour;

- minimum electricity consumption - an average of 0.046 kW/h per 1 ton of bulk cargo;

- versatility - suitable for loading any containers with any kind of grain, sunflower meal, granules, pellets, etc.;

- careful handling of grain and other bulk materials loaded into the container;

- changing the height and range of grain flight is made in just 1 second;

- quick installation on any suitable support;

- unlike the FulFiller container loading system, there is no need to hook the ZZ-120 grain loader directly onto the container using a loader;

- grain loader ZZ-120 can rotate 360 degrees around its axis, which allows you to load 2 containers in turn without the need to move containers;

- the presence of special pullers in the design, which speeds up the process of replacing the rubber band in the trimmer;

- the possibility of installing a frequency converter for smooth adjustment of the speed of rotation of the tape in the trimmer.

Video how to load meal into a container