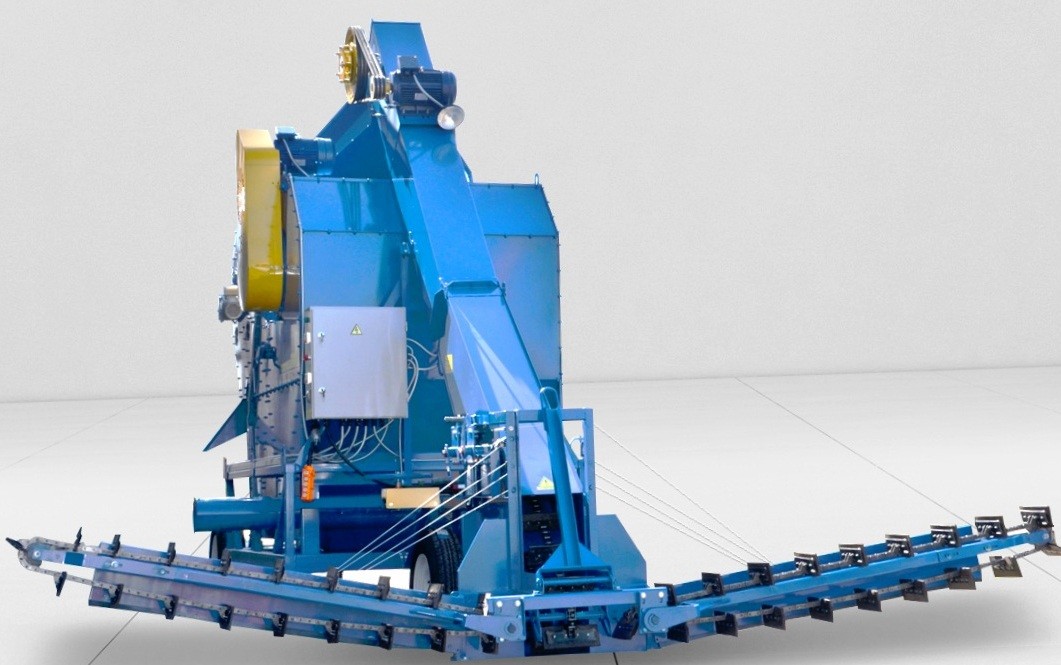

ОВС-70М3 -universal self-propelled machine for quick cleaning, drying, loading or reloading of grain. From the ОВС-70M and ОВС-70M2 machines, the ОВС-70M3 model is distinguished by the presence of an additional grain cleaning system on sieves, which allows to achieve high quality cleaning. In machines such as ОВС-70M and ОВС-70M2, grain heaps are cleaned of large and light impurities, as well as dust. The ОВС-70M3 machine through the use of an additional block of sieves with a brush cleaning system allows you to further cleanse the grain of small heavy impurities (for example, corn from ragweed, small stones and the like).

For the first time we combined in one self-propelled machine a powerful suction system, a high-quality grain cleaner, a grain thrower and a system for collecting dust and light impurities. As a result, we completely changed the technology of receiving, cleaning, drying and shipping grain for transportation or storage, making it easier and cheaper. These machines are very practical and easy to operate, safe and easy to operate, have the highest quality and reliability.

| Electric power consumption kW / h per 1 ton of grain | 0,25 |

| Number of operators to manage | 1 |

| Type of vehicle | self-propelled |

| Productivity, tone per hour | up to 70 |

| Grain loading height, meters | up to 9 |

| Coverage width of a pile of grain, meters | 5-6 |

| Type of drive | electric |

| Capacity, kW | 19,7 |

| Range of flight of grain, meters | up to 25 (adjustable) |

| Trimmer rotation angle, degrees | 257 |

| Height in working position, meters | 3,6- 4,3 |

| Mass,kg | 2550 |

| Lighting | 4 lights |

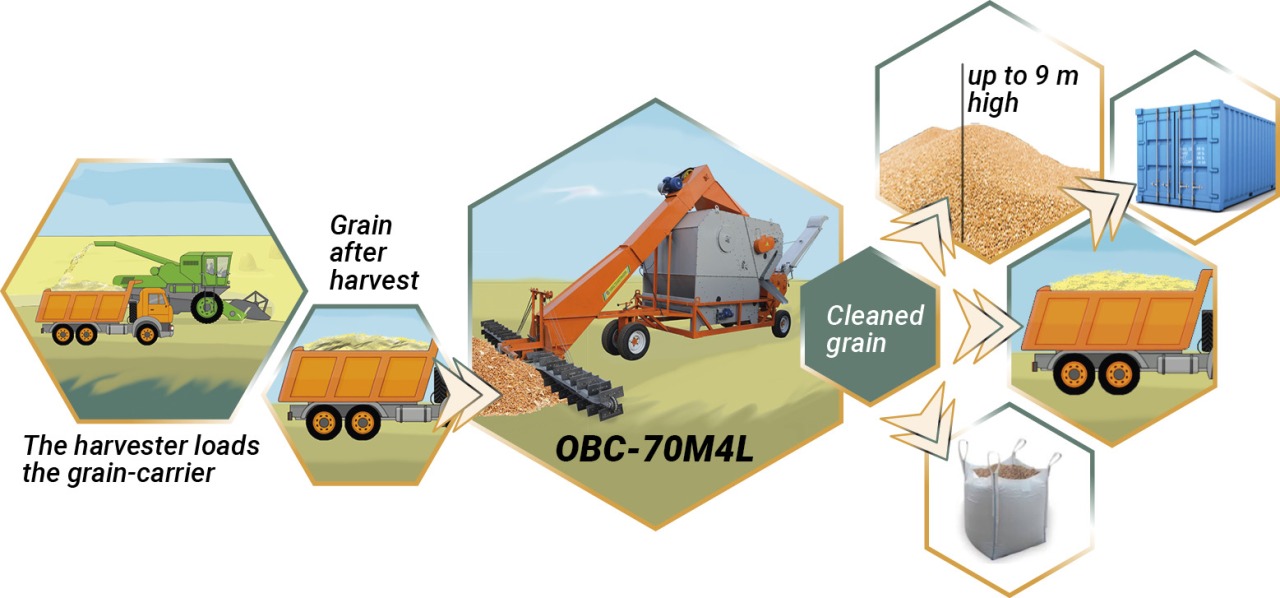

Let's consider in more detail how the ОВС-70M3 machine works:

- From the pile, a heap of grain through the loading elevator enters the receiving chamber, from which it enters the mesh conveyor in a uniform layer.

- A grain pile passes through a mesh conveyor, separating from large impurities. The size of the conveyor cell is from 4 to 19 mm.

- Large impurities are transported through the conveyor to the hopper, from where they are discharged from the machine to the left and to the right along the direction of the ОВС-70M3 movement.

- Grain material containing light impurities, after the conveyor falls on the separator, which shares the outgoing flow of grain with light impurities to improve the cleaning of grain material in the suction channel. The air stream created by the fan passes through the grain stream, picking up light impurities. The air flow rate is adjustable. This is the most effective way to remove light impurities.

- In the sedimentation chamber, light impurities are separated from the air flow due to centrifugal force. Clean air enters the fan again, and light impurities are removed by a screw from the machine to the right along the direction of the ОВС-70M3 movement.

- After the suction channel, the cleaned grain is fed by a conveyor (the lower part of which is made of sieves and has a brush cleaning mechanism) to the trimmer. During the movement of grain through the conveyor, it is cleaned of small impurities.

- The grain material that has fallen onto the trimmer tape accelerates and is unloaded from the machine through the trimmer pipe.

- The ОВС-70M3 operator can change the direction of grain flight by turning the trimmer through an angle of up to 257 degrees, i.e. to store or load refined grain into vehicles both from the rear and from the side, and even almost in front of the ОВС-70M3. Refined grain can be stored or loaded to a height of 9 meters and a range of up to 25 meters.

An advantage in comparison with ОВС-70M and ОВС-70M2 machines is that ОВС-70M3 has an additional system for cleaning grain on sieves, which allows to achieve high quality cleaning.

Advantages of ОВС-70M3 in comparison with other machines for cleaning and loading grain:

- For the first time we combined in one self-propelled machine a powerful suction system, a grain cleaner, a grain thrower and a system for collecting dust and light impurities. As a result, we created high-performance self-propelled machines with a complete technological cycle of processing grain material - acceptance, cleaning, drying and shipment of grain for transportation or storage.

- The presence of a triple grain cleaning system - on the mesh conveyor, aspiration system and sieves, which allows to achieve high quality grain cleaning, including from small heavy impurities such as ragweed, stones, etc.

- The technical features of our machines make it possible to reduce the dependence of the safety of the harvested grain on weather conditions due to the quick cleaning of the heap of high humidity with simultaneous drying, loading into vehicles or the formation of collars for storage.

- Emissions of dust and light impurities to the environment were eliminated, which positively affected the ecology and health of workers. Dust and light impurities are captured and can be used - to feed poultry or animals, sent to the manufacture of fuel pellets, fertilizers, etc. P.

- The process of moving grain from the warehouse to the stationary grain cleaning complex and vice versa is excluded; accordingly, there are no expenses for loading, transportation, unloading, reloading, transportation and unloading, and in case of shipment of grain to the buyer right after processing, also for loading grain into the buyer's grain carrier.

- The whole process of crop processing has been simplified - there is no need to design and build stationary complexes, make access roads to them, contain additional transport, loading equipment and personnel.

- Great productivity and minimal power consumption - 0.25 kWh per 1 ton of grain.

- All of the above, combined with an acceptable price, allows cleaning, loading, drying, re-sowing grain on our machines as quickly as possible with minimal costs.

ОВС-70М3 self-propelled grain cleaning complexes and their modifications ARE INTENDED FOR THE FOLLOW-UP OF THE FOLLOWING TECHNOLOGICAL OPERATIONS

work process

No need to spend a lot of time on the process

cleaning and shipment of grain.

Innovative plant technology saves 40%

time spent on processing.

Achieved through great efficiency,

minimum processing cost

grain, state compensation of expenses

for purchase and superior quality.

for a full grain processing cycle

One innovative mobile

the machine replaces the whole complex

post-harvest machines

grain processing.

Watch the ОВС-70M3 video review at the bottom of the DLG field

Watch the video how ОВС-70M3 works