The mobile grain cleaner OBC-355CMA with a cyclone and a loading auger is designed for cleaning and calibrating any grain and preparing high-quality seed material. It is an innovative combination of 5 sieves installed in a drum with adjustable rotation speed and angle of inclination, an adjustable powerful aspiration system, a large number of overhead valves and augers. The mobile grain cleaner OBC-355CMA has enormous possibilities and more than 50 applications ranging from preliminary cleaning of grain to high-precision calibration of grain at once from 3 different types of plants for seeds.

Mobile grain cleaning machine OBC-355CMA is easily transported by minibus, small truck or tractor on the road. This is the best solution for farms with several grain warehouses, as well as for businessmen providing grain cleaning services.

The basis of the mobile grain cleaner is a universal seed separator with a cyclone OBC-355C , which is installed on a platform with automobile wheels and a towing device, and is additionally equipped with an auger for loading grain. The auger can be rotated 250 degrees, which makes it possible to conveniently position the cleaner in relation to the grain pile. The auger is equipped with a quick-detachable hopper that allows you to load grain from bags, big bags, or from a body or trailer.

The front axle of the platform pivots for good maneuverability. The platform is equipped with 4 jacks, which ensures consistently efficient operation of the mobile grain cleaner on the ground and in warehouses with significant unevenness, as well as provides additional opportunities for adjusting performance.

The grain is cleaned from light impurities using an adjustable air flow in the aspiration system of the grain cleaning machine. The light impurities allocated by the aspiration system of the grain cleaner are partially discharged by the auger, and dust and very light impurities are sent through the air duct to the cyclone where they settle and pour down into a bag or big bag.

Cleaning and sizing of any grain by size is carried out on 5 large sieves. The sieve openings are effectively cleaned by the built-in brush and wooden roller system. The unloading of cleaned grain and impurities separated from the grain is carried out through the auger and guide trays in the lower part of the separator.

Mobile grain cleaning machine OBC-355CMA has many advantages, the main of which are:

- the possibility of transportation on the road as a trailer;

- quick bringing from transport to working position and vice versa (in 7-8 minutes);

- versatility - cleans any grain and has more than 50 applications;

- excellent quality of grain cleaning;

- excellent accuracy of seed sizing according to their size and aerodynamic properties;

- careful handling of grain, which is important when preparing seeds;

- the presence of a cyclone, which allows workers to work without respirators;

- adjustable performance;

- quick replacement of sieves

Mobile grain cleaning machine OBC-355CMA with a cyclone and auger provides the owner with unique opportunities for doing business in the field of agriculture. Take full advantage of this mobile grain cleaner and take your business to the next level.

| Height in transport position when towing, m | 3,15 |

| Height in working position, m | 3,65 |

| Height during transportation with removed wheels, m | 2,75 |

| Length with drawbar in transport position, m | 6,47 |

| Length with raised drawbar, m | 4,92 |

| Width in transport position, m | 2,19 |

| Width in working position (depends on position of feed auger), m | 2,19 - 5,67 |

| Weight, kg | 2100 |

| Loading auger turning angle, degrees | up to 250 |

| Productivity, ton per hour | up to 35 |

| Number of sieves installed in the grain cleaner, pieces | 5 |

| Time to replace all sieves, minutes | до 5 |

| Power consumption, kW | 6,6 |

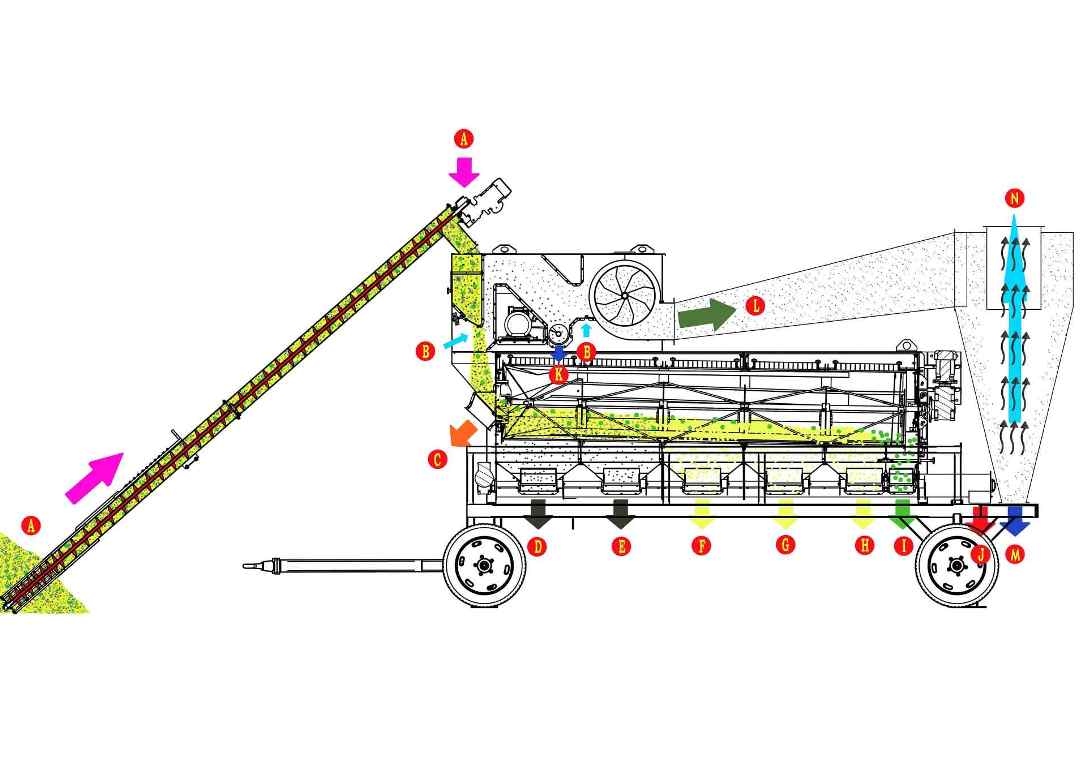

Scheme of operation of the OBC-355MCA mobile grain cleaner in the mode of cleaning and separating rapeseed, wheat and pea grains.

There are more than 50 operating schemes for the OBC-355MCA mobile grain separator.

A - loading uncleaned grain with a slow-speed auger from a heap or hopper

B - external air flow

C - grain unloading without cleaning with a separator (cleaning from light impurities)

D - unloading of small heavy impurities

E - unloading of a small fraction of the product (for example, rapeseed, millet)

F - unloading beaten grain, halves

G - unloading of the middle fraction of the product (e.g. wheat, barley)

H - unloading a large fraction of the product (e.g. peas, soybeans)

I - unloading of large waste

J - unloading through auger

K - unloading auger of light waste

L - air with dust and light impurities

М - dust and light impurities

N – air

Mobility

Mobile grain cleaning machine OBC-355CMA is easily transported by minibus, small truck or tractor on the road. This is an excellent solution for farms and agricultural enterprises that have several grain warehouses. This mobile grain cleaner is also great for service cooperatives that provide grain cleaning and seed preparation services.

Multifunctionality and versatility

The mobile grain separator OBC-355CMA can be used both for high-quality calibration and for preliminary cleaning or separation of grain and seeds from three crops at once. Grain can be fed into the aspiration chamber with an auger either directly from the heap or from a quick-detachable feed hopper. More than 50 variants of operation of the mobile grain cleaning machine OBC-355CMA with a cyclone, auger and a hopper are possible.

Quick transfer from transport to working position and vice versa

The process of bringing the mobile grain cleaner OBC-355CMA from the transport position to the working position takes no more than 8 minutes. This includes moving the auger to the working position by one person without the help of other people and mechanisms, connecting to the mains and other work. Bringing the OBC-355CMA to the transport position takes a similar amount of time and occurs in the reverse order.

The presence of a cyclone

The mobile grain cleaner OBC-355CMA has a cyclone that cleans the air from the aspiration system from dust and light impurities.

Cleaning efficiency

The efficiency of the process of cleaning and removing small impurities and crushed grain through the holes on the screens is very important. This directly affects the performance of the grain cleaning machine. In a grain cleaner with flat sieves, during operation, the mass of the grain layer lying on the lower sieve interferes with its effective cleaning, regardless of what exactly the sieves are cleaned with (brushes, balls, etc.). On the mobile drum grain cleaner OBC-355CMA, the sieves are cleaned in the upper part, where there is no grain. In this case, both brushes and wooden rollers are used for cleaning, which increases the efficiency of cleaning the sieves.

Availability of 4 jacks

On the cart of the mobile grain cleaner OBC-355CMA there are 4 jacks and horizon level sensors. This eliminates vibrations and allows you to install a mobile grain cleaning machine OBC-355CMA in any grain warehouse or on any site with significant irregularities. Using jacks, you can additionally adjust the angle of inclination of the drum with sieves and, accordingly, the performance of the grain cleaning machine.

Calibration accuracy

Constant movement and absence of vibrations allows each grain or particle to enter more easily into the holes on the sieves. That is why drum seed cleaners are often used for accurate calibration. 5 sieves are installed in the mobile grain cleaning machines OBC-355CMA, which makes it possible to very accurately separate any grain or a mixture of different seeds.

Flexibility of operation

In a grain cleaning machine with flat sieves, the upper sieve can remove only coarse impurities, and the lower one - crushed and small grains and impurities. In the mobile grain cleaning machine OBC-355CMA, each sieve can be used to remove different or identical grains and impurities. The operation of the separator changes rapidly depending on the needs. During calibration, the number of sieves determines the maximum number of fractions into which the grain can be divided. In the mobile grain cleaner OBC-355CMA, 5 sieves are installed at once. This makes it possible to simultaneously separate and purify a mixture of seeds of three different plants at once, which is of great importance in organic farming and growing environmentally friendly products.

Adjustable rotation speed and inclination of the drum with sieves

Only some models of grain cleaning machines with flat sieves allow adjusting the working speed and the inclination of the sieves. In any flat screen cleaner, an increase in speed and tilt will result in grain bouncing and reduced sorting accuracy. In the mobile grain cleaner OBC-355CMA, changing the speed and tilt improves the calibration accuracy and increases productivity. This provides more application possibilities. Changing the speed of rotation of the drum is done by adjusting it electronically. Changing the angle of inclination of the drum is carried out manually by rotating the large handle at the back of the grain cleaner. 4 jacks installed on the OBC-355CMA trolley also allow additional adjustment of the sieves tilt.

Gentle handling of grain and seeds

The grain is loaded with a screw with a low rotation frequency. In the process of further cleaning and separation, seeds and grain move along the mobile grain separator OBC-355CMA by gravity, which eliminates its damage.

Application for products that are difficult to sort

Mobile grain cleaner OBC-355CMA is used for separation and calibration of a wide range of products (for example: fibers and cotton seeds, corn grains with high moisture content, balls, etc.). It can be used for both high quality calibration and pre-cleaning of any grain and seed.

Quick replacement of sieves

The speed at which sieves are changed plays an important role in the selection of sieves for cleaning very clogged grain. This is also important when separating and cleaning a mixture of seeds from different plants. Thanks to the devices specially installed on each sieve, the process of replacing all 5 sieves in the mobile grain cleaner OBC-355CMA is carried out in less than 5 minutes. Quick replacement of sieves saves time, speeds up the process of grain cleaning and seed calibration.

Watch the video how to quickly change the sieve

Watch the video of how a mobile grain cleaner works