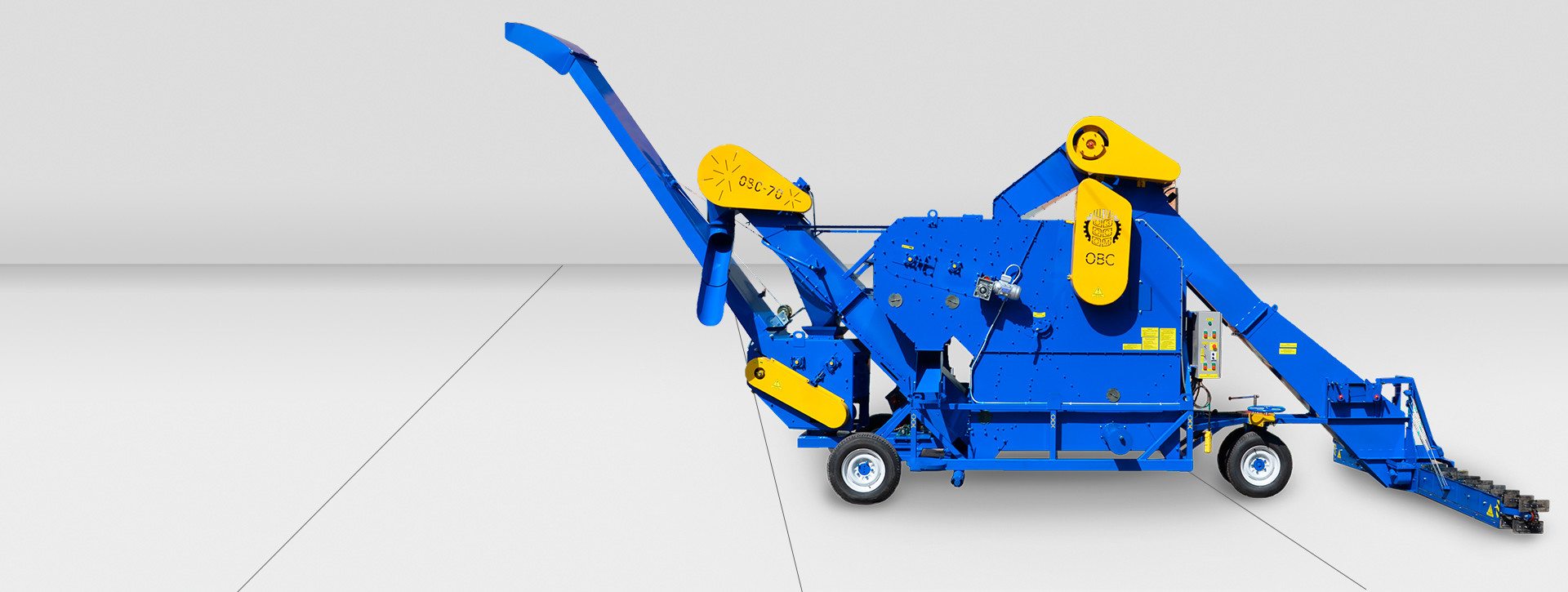

OBC-70M4L is a self-propelled high-performance combination of a grain cleaning machine, a grain thrower and a grain loader, which minimizes human labor when cleaning, shipping and moving grain. This is the fourth generation of well-proven machines of previous generations OBC-70ML, OBC-70M2L and OBC-70M3L.

OBC-70M4L differs from OBC-70M3L by the presence of an additional screw conveyor, which removes small impurities separated by sieves into a single waste heap with light impurities separated by aspiration and a mesh conveyor with large impurities.

The OBC-70M4L self-propelled grain cleaning complex differs from the OBC-70ML and OBC-70M2L machines by the presence of an additional grain cleaning system on sieves, which allows achieving high-quality cleaning. In machines such as OBC-70M, OBC-70M2, OBC-70ML and OBC-70L, the grain heap is cleaned from large (more than 5 mm) and light impurities, as well as dust. The OBC-70M4L machine, due to the use of an additional block of sieves with a brush cleaning system, allows you to additionally clean the grain from small heavy impurities (for example, ragweed seeds and other weeds, small stones, etc.).

Unlike OBC-70M, OBC-70M2, OBC-70M3 and OBC-70M4, the cleaned grain can be fed by the conveyor not into the trimmer, but directly into the trailer or spilled down or to the sides along a special chute that rotates 360 degrees. This has an advantage - minimal injury to the grain.

If the grain needs to be thrown or loaded to a height of more than 3 meters, then this is done using the trimmer available for the OBC-70M4L, on which the trimmer pipe is installed (included in the OBC-70M4L package).

OBC-70M4L is a self-propelled high-performance grain cleaning complex whose price is affordable for farmers and agricultural producers. It has many advantages and is a versatile solution for post-harvest grain and seed processing. If you decide to buy a universal grain cleaning complex OBC-70M4L, then this decision will quickly pay off and will solve all issues with cleaning, moving and shipping grain.

| Productivity, tone per hour | up to 80 |

| Type of drive | electric |

| Total installed capacity, kW | 19,52 |

| Electric power consumption kW/h per 1 ton of grain | 0,27 |

| Height in working position, meters | 3,61-4,7 (adjustable) |

| Grain pickup width, meters | 5-6 |

| Mass,kg | 3019 |

| Grain loading height, meters | 3-9 (adjustable) |

| Grain flight range, m | up to 23 (adjustable) |

| Machine type | self-propelled |

| Number of operators for control | 1 |

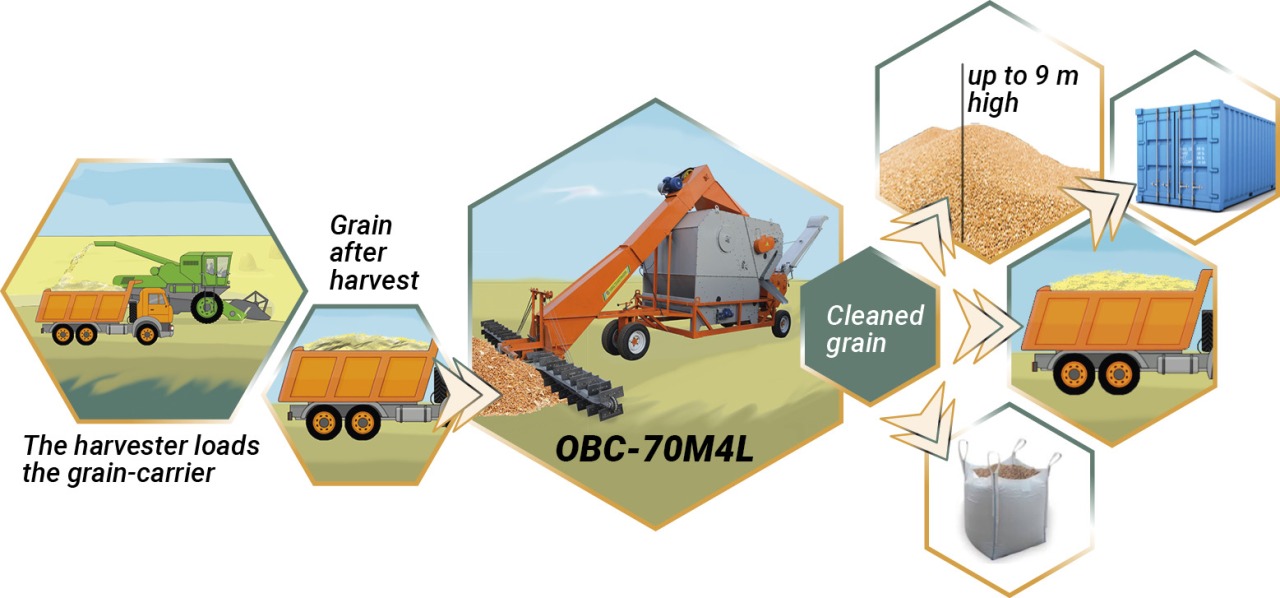

Self-propelled grain cleaner, grain thrower and grain loader OBC-70M4L works in the following sequence:

- From the pile, the heap of grain through the loading elevator enters the receiving chamber, from which it flows in a uniform layer onto the mesh conveyor.

- The grain heap passes through the mesh conveyor, separating from large impurities. The size of the conveyor cell is from 5 to 19 mm.

- Large impurities along the conveyor enter the bunker, from where they are removed from the self-propelled grain cleaner OBC-70M4L to the left and right in the direction of travel.

- Grain material containing light impurities, after the conveyor, goes to a separator, which divides the outgoing flow of grain with light impurities to improve the cleaning of grain material in the aspiration channel. The air flow created by the fan passes through the grain flow, picking up light impurities.

- In the sediment chamber, light impurities are separated from the air flow by centrifugal force and gravity. Clean air enters the fan again, and light impurities are removed by a screw from the car to the right in the direction of movement OBC-70M4L.

- From the aspiration channel, the cleaned grain is fed by a conveyor (the lower part of which is made of sieves and has a cleaning mechanism) into the trimmer or is carefully unloaded through the conveyor head into a trailer, big-bag or onto a heap. By simply moving the shutter, the grain feed into the trimmer is blocked and the grain is discharged through the top of the conveyor and the guide chute.

- During the movement of grain along the conveyor, it is cleaned from small impurities, which are removed to the right side of the machine, forming a single pile of waste.

- The operator OBC-70M4L can change the direction of flight of the grain by turning the trimmer through an angle of up to 250 degrees, i.e. store or load grain into vehicles both from the back and from the side and even almost in front of the OBC-70M4L.

- The cleaned grain can be stored or loaded through the trimmer to a height of 10 meters and a range of up to 25 meters. If the trimmer is turned off and the conveyor is used, the loading height reaches 3 meters.

Self-propelled grain cleaner, grain thrower and grain loader OBC-70M4L in comparison with other grain cleaning machines has the following main advantages:

- OBC-70M4L, unlike other grain cleaning machines, can independently load grain into a truck, trailer or container without grain throwers, loaders, norias.

- OBC-70M4L is a self-propelled, not a stationary grain cleaning and loading machine and does not require additional costs to put it into operation.

- OBC-70M4L is a mobile grain cleaning and loading machine and can be easily transported to another current, grain warehouse or to another farm.

- High productivity - 50-80 tons per hour (depending on the type, moisture content and degree of grain contamination).

- High-quality cleaning and separation of grain: by specific gravity due to the use of an adjustable air flow (as in aerodynamic separators) and by size by using a mesh with different mesh sizes and sieves with a cleaning system.

- The minimum electricity consumption for cleaning and loading is no more than 0.25 kW / hour per 1 ton of grain.

- The use of OBC-70M4L makes it possible to dry the grain during grain cleaning by reducing the moisture content to 4%.

- Self-propelled grain cleaner, grain thrower and grain loader OBC-70M4L does not require expensive service during operation.

- Minimal grain damage.

- Using OBC-70M4L you can easily solve the problem of quick cleaning of a large amount of grain.

- Good price and quick payback of the OVS-70M4L grain cleaning complex

If you are engaged in the cultivation of cereals and seed production - purchase OBC-70M4L.

Watch the video review of OBC-70M4L

Watch the video how OBC-70M4L works

Self-propelled grain cleaning complexes OBC-70M4L ARE DESIGNED FOR PERFORMANCE OF THE FOLLOWING TECHNOLOGICAL OPERATIONS

workflow time

process of cleaning and unloading grain.

The innovative plant technology saves 40%

of processing time.

minimal cost of grain processing,

state compensation for purchase costs

and excellent quality of equipment.

for a complete grain processing cycle.

machine replaces a whole range of

post-harvest grain handling machines.

Video on how to quickly clean grain