Self-mobile grain cleaner

and grain loader ОВС-70L

Performs the functions of a grain cleaning machine

and grain loader. The main difference between the ОВС-70L and

the OBC-70M is that the cleaned grain is not fed into

the trimmer by the transporter, but directly into a trailer,

a big bag or poured down. The advantage of this machine

is that the damage to the grain is minimal.

ОВС-70L - is a self-propelled high-performance hybrid of a grain cleaning machine and a grain loader. The main difference between ОВС-70L and ОВС-70M is that the ОВС-70L has an elongated unloading elevator, but there is no trimmer. At ОВС-70L, the cleaned grain is not conveyed by the conveyor to the trimmer, but directly to the trailer, big-run, hopper, or poured down.

However there is and the disadvantage is the maximum possible height for loading - up to 3,5 meters.

Functions performed by the self-propelled heap cleaner ОВС-70L:

- cleaning grain heaps of legumes, grains, cereals, ears, corn, sunflower, rapeseed, sorghum, etc .;

- loading grain directly into vehicles with a side height of up to 3 meters;

- loading grain into big bags, bags, bins, loader buckets, etc .;

- mechanical shoveling of grain, accompanied by its simultaneous cleaning, as well as partial drying in open areas or granaries.

The self-propelled grain cleaning machine OBC-70L with an extended elevator is the simplest machine among the self-propelled grain cleaning complexes that are produced by the agricultural machinery plant. The price of a grain cleaner - grain loader OBC-70L is also very affordable.

| Electric power consumption kW / h per 1 ton of grain | 0,2 |

| Number of operators to manage | 1 |

| Type of vehicle self-propelled | self-propelled |

| Productivity, tone per hour | up to 70 |

| Grain loading height, meters | up to 3,2 |

| Coverage width of a pile of grain, meters | 5-6 |

| Type of drive | electric |

| Capacity, kWt | 14,35 |

| Height in working position, meters | 3,65 |

| Weight, kg | 2295 |

| Lighting | 4 lights |

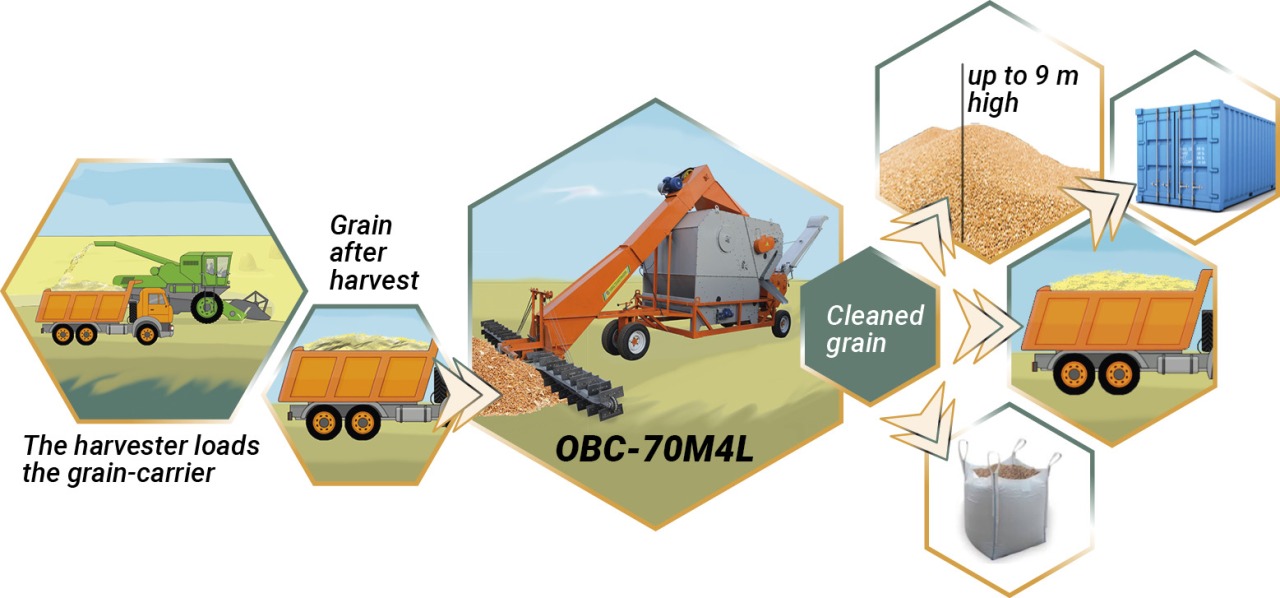

ОВС-70L operates in the following sequence:

- a pile of grain from the pile along the loading elevator is fed into the receiving chamber, from there it enters the conveyor in an even layer;

- when passing through a mesh conveyor, the grain material is cleaned of large impurities;

- large impurities are discharged by the conveyor to the left and to the right of the ОВС-70L;

- the pre-cleaned grain heap, which still contains light impurities, is sent to the divider, where the flow of grain material is divided to ensure better grain handling in the suction channel. Light impurities are picked up by the stream of air created by the built-in fan. This method is most effective for separating light impurities. Air flow rate adjustable;

- getting into the sedimentation chamber, light impurities are released from the air stream under the influence of centrifugal force. The purified air is again supplied to the fan, and light impurities are discharged by a screw to the right of the ОВС-70L;

- from the suction channel, the cleaned grain enters the conveyor and is further discharged from the machine through the chute;

- ОВС-70L operator can quickly change the direction of grain unloading by turning the gutter.

Heap cleaner ОВС-70L self-propelled has a number of advantages, in comparison with other grain cleaning machines:

- ОВС-70L independently loads grain into the car body, container or trailer or stores it. The participation of grain throwers, loaders, nori is not required.

- ОВС-70L is a self-propelled (not stationary) grain cleaning and loading machine. For the introduction of its operation does not require additional costs.

- ОВС-70L is a mobile complex, which can easily be moved to another current, granary, or even to another farm.

- It features great performance. Depending on the type of grain, its moisture content and the degree of contamination, it can process up to 70 tons per hour.

- It carries out high-quality grain cleaning and its separation: according to specific gravity (using adjustable air flow, by the type of aerodynamic separators) and by size (using a grid with cells of different sizes).

- The energy consumption for cleaning and loading is minimal and amounts to 0.2 kW / h per 1 ton of grain.

- ОВС-70L performing grain cleaning, also performs its drying. The moisture content of the grain material is reduced to 2%.

- During the operation of ОВС-70L, expensive maintenance is not required.

- Provides minimal grain damage.

ОВС-70L2 ― аn improved model of a heap cleaner - ОВС-70L grain loader. ОВС-70L2 differs from ОВС-70L in the presence of an additional motor gearbox and an advanced remote control for turning ОВС-70L2 when moving. This facilitates the control of the ОВС-70L2 and allows you to easily change the direction of movement of the machine without the use of physical force. In ОВС-70L2 there is also the same steering wheel as on ОВС-70L (for manual control of ОВС-70M2 if necessary).