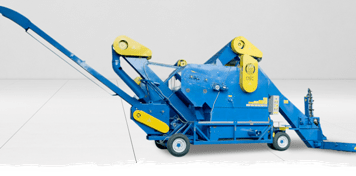

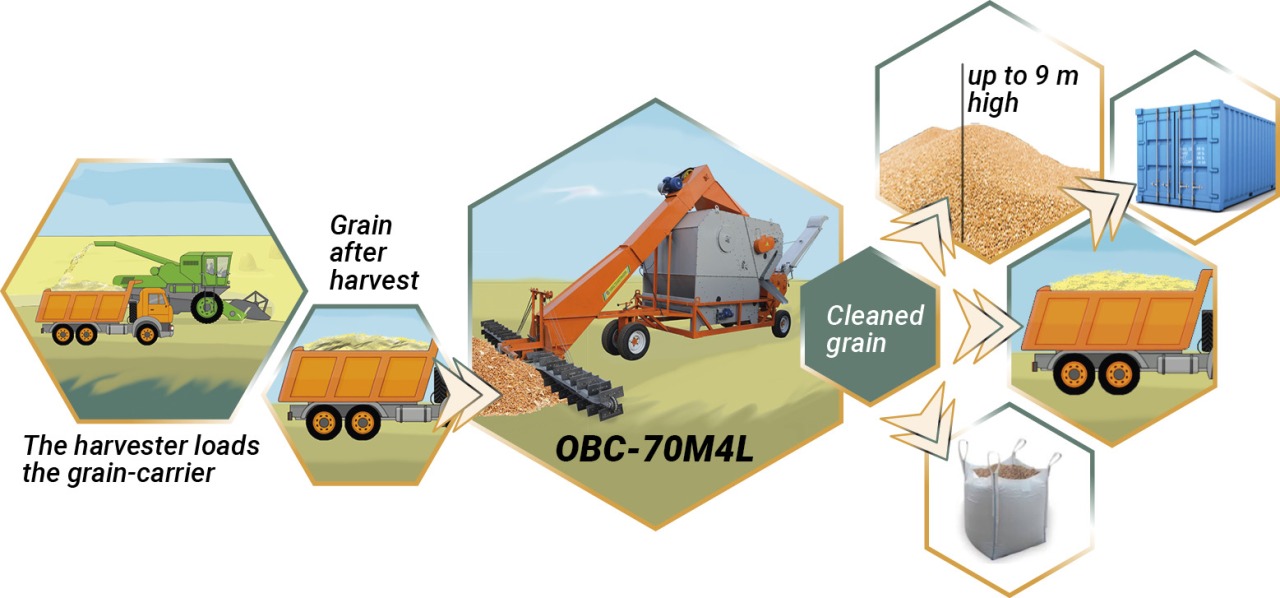

Self-propelled ОВС-70МP heap cleaner is a self-propelled high-performance combination of a grain cleaning machine, a grain thrower and a grain loader. In contrast to the ОВС-70P, in addition to the elongated unloading elevator, the ОВС-70МP is also equipped with a trimmer with a trimmer pipe.

Unlike ОВС-70M, ОВС-70МP has an elongated unloading elevator. The cleaned grain can not only fly out through the trimmer pipe, but also sleep out in the trailer or to the sides along a special gutter that rotates 360 degrees. There is an advantage in this - the grain is less injured, and the disadvantage is the maximum loading height through the trench up to 3 meters. Through the trimmer pipe, the loading height is up to 9 meters.

| Electric power consumption kW / h per 1 ton of grain | 0,25 |

| Number of operators to manage | 1 |

| Type of vehicle | self-propelled |

| Productivity, tone per hour | up to 70 |

| Grain loading height, meters | up to 9 |

| Coverage width of a pile of grain, meters | 5-6 |

| Type of drive | electric |

| Capacity, kW | 18,15 |

| Height in working position, meters | 3,65- 4,3 |

| Mass,kg | 2590 |

| Lighting | 4 lights |

ОВС-70МP heap cleaner works as follows:

- From the pile, a heap of grain through the loading elevator enters the receiving chamber, from which it enters the mesh conveyor in a uniform layer.

- A grain pile passes through a mesh conveyor and is separated from large impurities.

- Large impurities are discharged from the machine to the left and right along the ОВС-70МP conveyor.

- Grain heap containing light impurities, after the conveyor enters the divider, which shares the outgoing flow of grain with light impurities to improve the cleaning of the grain material in the suction channel. The air stream created by the fan passes through the grain stream, picking up light impurities. Airflow is adjustable. This is the most effective way to remove light impurities, the so-called fluidized bed of grain.

- In the sedimentation chamber, light impurities are separated from the air flow due to centrifugal force. Clean air enters the fan again, and light impurities are removed by a screw from the machine to the right in the direction of movement of the machine.

- After the suction channel, the cleaned grain is unloaded from the machine through a special chute to a height of 3 meters or flies through the trimmer pipe to a height of up to 9 meters (adjustable).

- The ОВС-70МP operator can change the direction of grain unloading by turning a special trough 360 degrees or a trimmer 254 degrees around its axis.

- Grain from the gutter can be sent directly to big bags, bins, etc.

Advantages of ОВС-70МP in comparison with ОВС-70M and ОВС-70P:

- ОВС-70МP - a more versatile self-propelled grain cleaning and loading complex, combining the advantages of both ОВС-70M and ОВС-70P;

- from ОВС-70МP, the cleaned grain can not only fly out through the trimmer pipe as in ОВС-70M, but can fall out down into the trailer, big-bag, hopper or to the sides along a special trough like ОВС-70P;

- less power consumption and less damage to grain in comparison with ОВС-70M when unloading grain from ОВС-70МP through the gutter;

- unlike ОВС-70P, the ОВС-70МP machine has a trimmer with a pipe that allows unloading grain to a height of 9 meters and a distance of up to 25 meters.

Advantages of ОВС-70МP in comparison with other machines for cleaning and loading grain:

- A pile of grain from the pile through the loading elevator enters the ОВС-70МP receiving chamber, from which it enters the mesh conveyor in a uniform layer.

- A grain pile passes through a mesh conveyor and is separated from large impurities.

- Large impurities are discharged from the machine to the left and right along the ОВС-70МP conveyor.

- Grain heap containing light impurities, after the conveyor enters the divider, which shares the outgoing flow of grain with light impurities to improve the cleaning of the grain material in the suction channel. The air stream created by the fan passes through the grain stream, picking up light impurities. Airflow is adjustable. This is the most effective way to remove light impurities, the so-called fluidized bed of grain.

- In the sedimentation chamber, light impurities are separated from the air flow due to centrifugal force. Clean air enters the fan again, and light impurities are removed by a screw from the machine to the right in the direction of movement of the machine.

- After the suction channel, the cleaned grain is unloaded by the conveyor from the machine either into the trimmer, from where it flies out through the trimmer pipe, or poured down into the trailer or to the sides along a special chute that rotates 360 degrees.

- The ОВС-70МP operator can change the direction of grain unloading by turning a special trough 360 degrees or a trimmer 254 degrees around its axis.

ОВС-70МP self-propelled grain cleaning complex is intended for the performance of the following technological operations

work process

No need to spend a lot of time on the process

cleaning and shipment of grain.

Innovative ОВС-70МP machine saves 40%

time spent on grain processing.

Achieved through great efficiency,

minimum processing cost

grain, state compensation of expenses

for purchase and superior quality.

for a full grain processing cycle

One innovative mobile

ОВС-70МP machine replaces the whole complex

post-harvest machines

grain processing.

Watch the video how the ОВС-70МP works in the grain thrower mode

Watch the video how ОВС-70МP works in grain loader mode