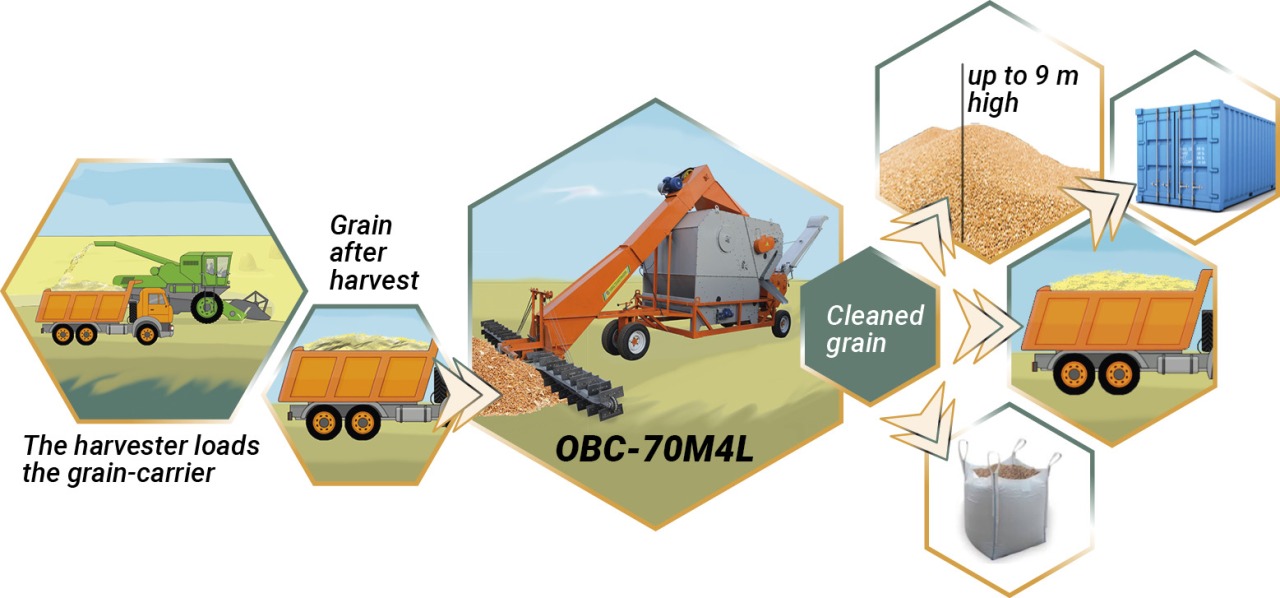

For the first time, we combined in a single self-propelled machine of the ОВС-70M type a powerful aspiration system, a grain cleaner, a grain thrower and a system for collecting dust and light impurities. As a result, we completely changed the technology of receiving, cleaning, drying and shipping grain for transportation or storage, making it easier and cheaper. These machines are very practical and easy to operate, safe and easy to operate, have the highest quality and reliability.

The self-propelled heap cleaner ОВС-70M and ОВС-70M2 performs the following functions:

- Cleaning of any legumes, ears, cereals, corn, sunflower, rape, sorghum, etc.

- Loading refined grain in vehicles. Available board height up to 4.5 m.

- Mechanical shoveling (rearrangement). It is carried out both in open areas and in grain warehouses. At the same time, grain is cleaned and dried.

Watch the feature video ОВС-70М

| Electric power consumption kW / h per 1 ton of grain | 0,245 |

| Number of operators for control | 1 |

| Type of vehicle | self-propelled |

| Productivity, tone per hour | up to 70 |

| Grain loading height, meters | up to 9 |

| Grain heap fence width, meters | 5-6 |

| Type of drive | electric |

| Power consumption, kW | 18,35 |

| Range of flight of grain, meters | up to 25 (adjustable) |

| Trimmer rotation angle, degrees | 257 |

| Height in working position, meters | 3,48- 4,5 (adjustable) |

| Mass,kg | 2540 |

| Lighting | 4 lights |

- For the first time we combined in one self-propelled machine a powerful pneumatic separation system, a grain cleaner, a grain loader, a grain thrower and a system for collecting dust and light impurities. As a result, we created high-performance self-propelled machines with a complete technological cycle of processing grain material - acceptance, cleaning, drying and shipment of grain for transportation or storage.

- The technical features of our machines make it possible to reduce the dependence of the safety of the harvested grain on weather conditions due to the quick cleaning of the heap of high humidity with simultaneous drying, loading into vehicles or the formation heaps for storage.

- Eliminated emissions of dust and light impurities in the environment, which positively affected the ecology and health of workers. Dust and light impurities are captured and can be used - to feed poultry or animals, sent to the manufacture of fuel pellets, fertilizers.

- The process of moving grain from the warehouse to the stationary grain cleaning complex and vice versa is excluded; accordingly, there are no expenses for loading, transportation, unloading, reloading, transportation and unloading, and in case of shipment of grain to the buyer right after processing, also for loading grain into the buyer's grain carrier.

- The whole process of crop processing has been simplified - there is no need to design and build stationary complexes, make access roads to them, contain additional transport, loading equipment and personnel.

- Great productivity and minimal power consumption - 0.25 kWh per 1 ton of grain.

- All of the above, combined with a low price, allows you to process grain as quickly as possible on our machines with minimal cost.

ОВС-70M and ОВС-70M2 self-propelled grain cleaning complexes are designed for the performance of the following technological operations

the working process

No need to spend a lot of time on the process

harvesting and shipment of grain.

Innovative plant technology saves 40%

time spent on grain processing.

Achieved through great efficiency,

minimum processing cost

grain, state compensation of expenses

for purchase and superior quality.

for a full grain processing cycle

One innovative mobile machine replaces

grain processing.

Self-mobile cleaner of heap grain thrower ОВС-70M2 - an improved model ОВС-70M grain thrower. ОВС-70M2 differs from ОВС-70M in the presence of an additional motor gearbox and an advanced remote control for turning ОВС-70M2 when moving. This facilitates the control of the ОВС-70M2 and allows you to easily change the direction of movement of the machine without the use of physical force. In OVS-70M2 there is alsomanual steering as on ОВС-70M (for manual control of ОВС-70M2 if necessary).

ОВС-70M2 cleans the grain of large impurities (larger than grain) on the mesh conveyor and light (lighter than a whole grain) impurities using an adjustable aspiration system, and also makes a rearrangement or loading of grain into vehicles. ОВС-70M2 combines the advantages of a self-propelled grain cleaning machine and a grain thrower.